Energie und CO2 einsparen durch Investieren

Profitieren Sie nicht nur von den aktuellen Fördermaßnahmen zur Energie- und Ressourceneffizienz in der Wirtschaft

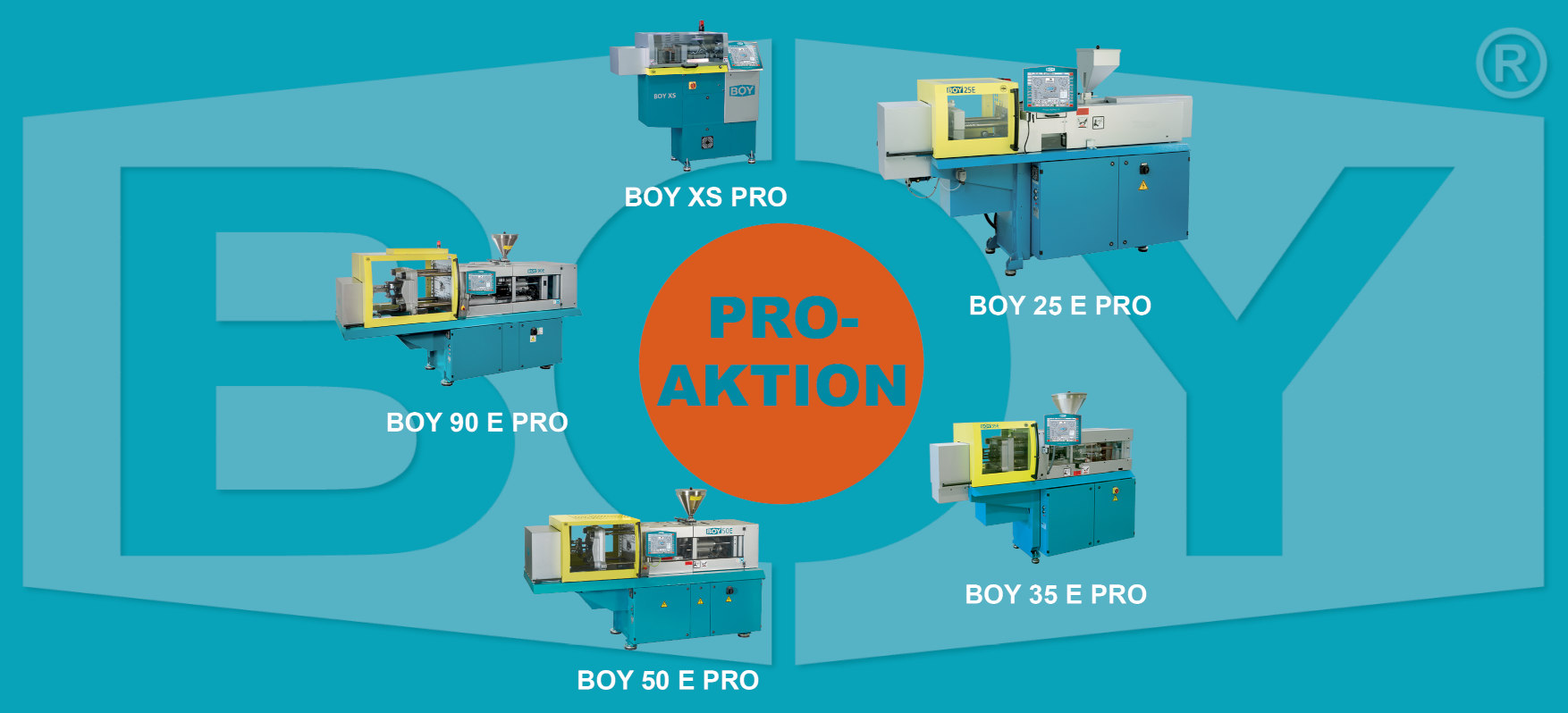

Spritzgießmaschinen von BOY

Fast 50.000 mal Erfahrung in 50 Jahren

1968 begann die Erfolgsgeschichte von BOY mit der Markteinführung der BOY 15. Ihre Kompaktbauweise, die einfache Bedienbarkeit sowie die wirtschaftliche Effizienz und die zum Teil völlig neuen technischen Lösungen revolutionierten die vollautomatisierte Fertigung im Kunststoffspritzguss.

Doch wir ruhten uns nicht auf den Lorbeeren von damals aus: Durch stetige Forschung und konsequente Weiterentwicklung bieten wir heute eine ganze Reihe von Spritzgießmaschinen für alle Anforderungen an. Seit unserer Firmengründung haben wir fast 50.000 Spritzgießmaschinen in alle Kontinente geliefert. Somit ist BOY führend für Spritzgießmaschinen im Schließkraftbereich bis 1.250 kN.

Ganz gleich, ob Sie beispielsweise Zahnräder mit 2 mm oder Frisbee-Scheiben mit 300 mm Durchmesser produzieren wollen – wir haben die optimale technische Lösung für Sie.

Spezial-Spritzgießverfahren mit BOY