Perfect results in all areas

Special injection moulding procedure using BOY

In addition to the processing of thermoplastic material, continuous research and developments, as well as close cooperation with customers and renowned specialists helped BOY to become an established supplier for special applications. In nearly all industrial sectors, many different materials are processed:

- Electrical, computer, office, telecommunications, and clock-making industries

- Automotive, cosmetics and packaging industries

- Mechanical, equipment, and apparatus engineering

- Pharmaceutical industry

- Aviation, space and defence industries

BOY offers special machine configurations for various applications and materials.

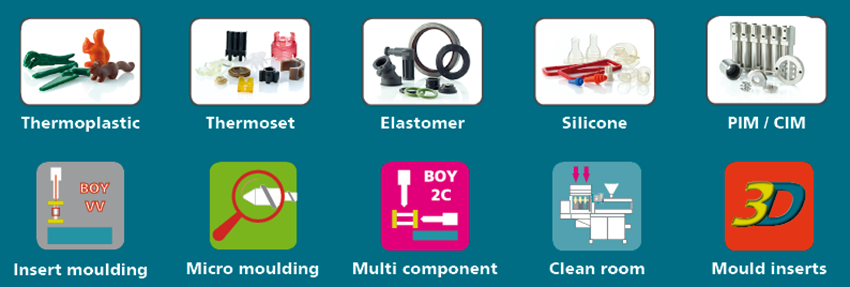

The versatility of BOY injection moulding machines is demonstrated by their ability to process a multitude of special applications:

- Insert moulding

- Micro injection moulding

- LSR (Liquid Silicone Rubber)

- Elastomer processing

- Thermoset processing

- CIM (Ceramic Injection Moulding)

- MIM (Metal Injection Moulding)

- Clean-room technology

- PET preforms

Expert know-how

The specialists at BOY are at all times available to you for working out individual concepts and procedures. Alternatively, you may test your materials and moulds under real-life conditions in the showroom at BOY.

BOY injection moulding machines: solutions for all plastic processing applications

In five decades, BOY has sold nearly 50.000 injection moulding machines worldwide. During this time, BOY has become a well-known supplier of machines designed for many applications. Besides the processing of thermoplastics, BOY designed special machine configurations for different applications and special materials through continuous research and the support of customers and well-known specialists. These special designs and technical development capabilities has enabled BOY to meet every special application in the plastics industry.

The following applications and special solutions are possible on BOY injection moulding machines: Thermoplastic, elastomer, silicone, PIM, hotmelt, insert moulding, micro injection moulding, and clean room techniques.