Press Release 01/2022

Neustadt-Fernthal, February 2022

BOY starts its international trade fair presence at Chinaplas 2022

For the German injection moulding machine manufacturer BOY the trade fair year 2022 starts full of expectations with its participation in the Chinaplas in Shanghai from 25th to 28th April, 2022.At the major event in Shanghai, BOY will present two compact injection moulding machines from its comprehensive product programme on its booth 2.1G75.

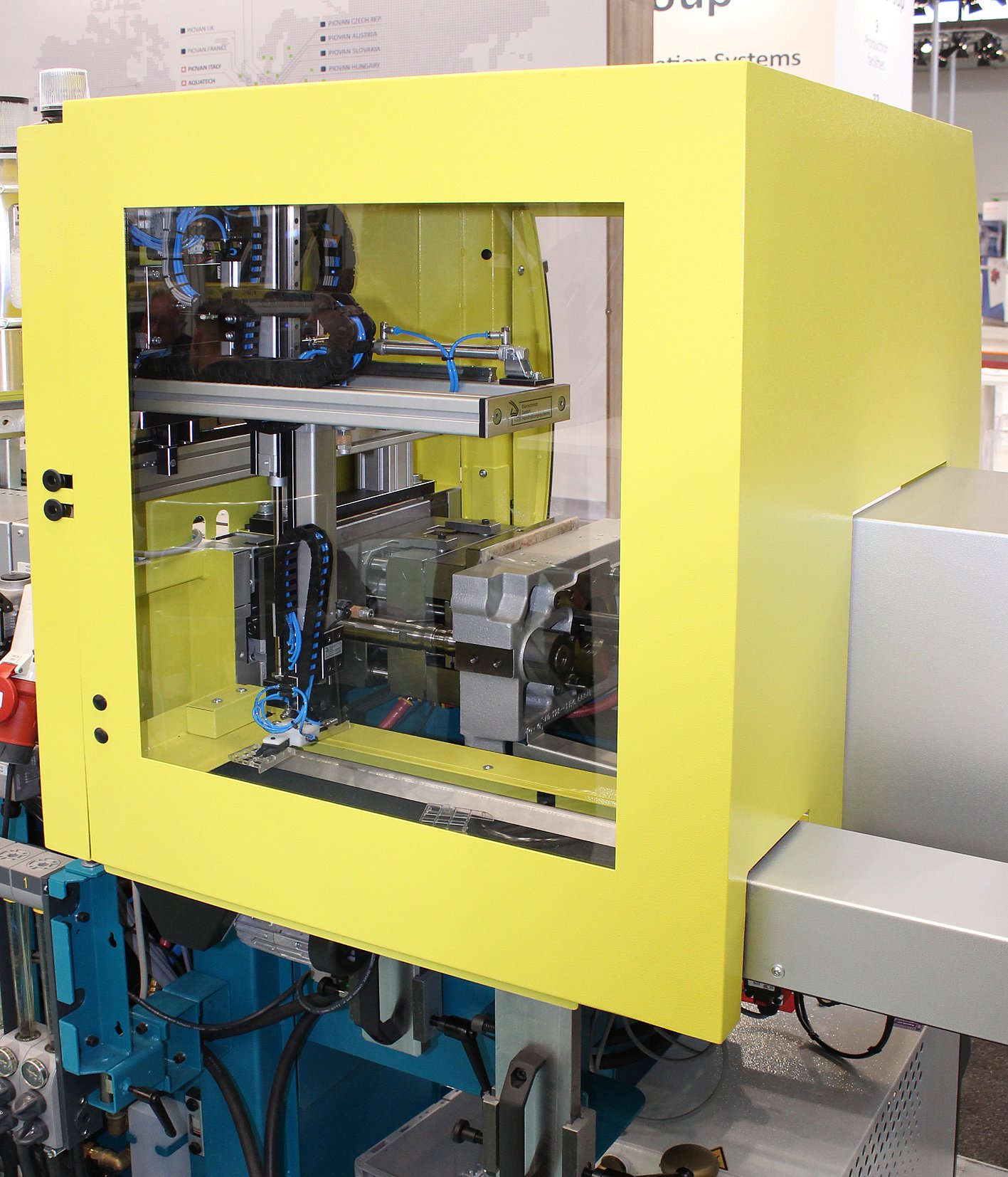

On a BOY 25 E the two lateral frame parts of the filter elements for a medical respiratory mask will be prefabricated. In a subsequent work step, an elastomer sealing lip is attached to the pre-moulded frame part. The frame parts injected from a Polycarbonate (Makrolon 2207) are removed from the 2-cavity mould by a gripper. Subsequently the sprue is separated and then the parts are placed on a conveyor belt. The pneumatically operated handling and the conveyor belt are positioned in a space-saving manner under the safety gate of the BOY 25 E. The long-standing success model with 250 kN clamping force and a footprint of only 1.8 m² has a cantilevered two-platen clamping unit for easy accessibility and individual automation equipment.

With seven different screw diameters, the BOY 25 E offers plasticising volumes of up to 76.5 cm³. The energy-efficient servo-motor pump drive ensures a dynamic operation at very smooth running.

The German manufacturer is also presenting its BOY XS machine model with a medical technology application. The machine produces a small Osteosynthesis plate made of PP, which is used in surgery to fix bone fractures. The injection moulding machine, which is mainly used for micro injection moulding and for very small parts, has a clamping force of 100 kN. In its smallest injection moulding machine, BOY also relies on the proven reciprocating plasticizing screw, which works according to the "first in - first out" principle. With screw diameters between 8 and 18 mm, plasticising volumes of 0.06 to 15.3 cm³ are possible in continuous industrial operation.

Christian Storz, Head of Export at BOY, expects a signal effect from the participation in Chinaplas: "We are convinced that we are the ideal partner for users in the Chinese plastics market with our ultra-compact injection moulding machines and high-precision solutions "Made in Germany". Together with our long-standing representative Andeli Co., Ltd., we want to confirm our traditional, successful presence at the trade fair this year again and we are looking forward to the visits and discussions with numerous customers and new interested parties."