Well-proven design

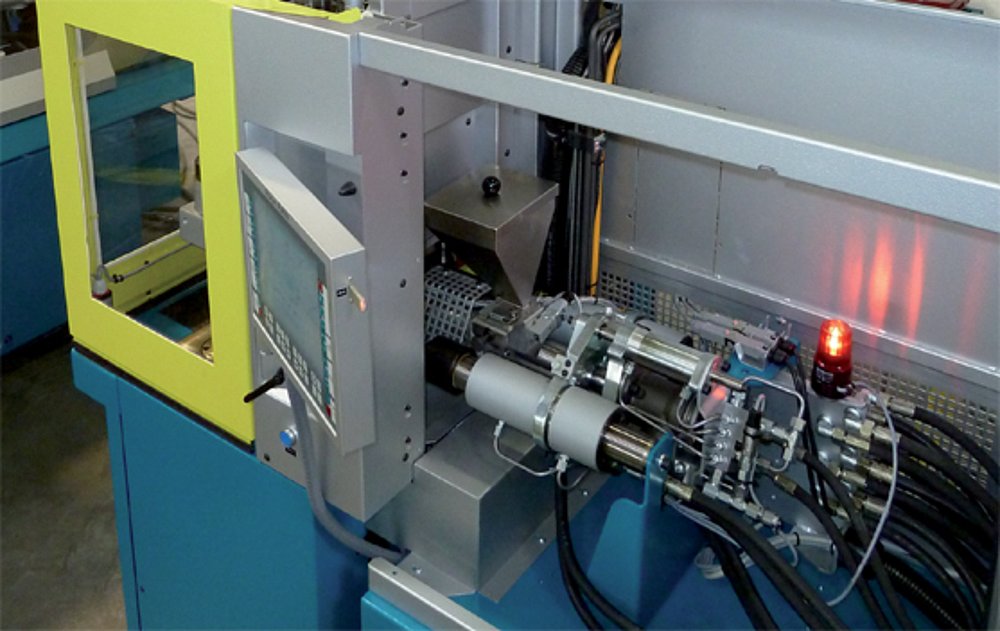

Insert moulding machine BOY 35 E VV

The basic concept of the 35 E VV is quiet similar to the BOY 35 E horizontal injection moulding machine - merely the injection and clamping unit are arranged vertically by a 90° rotation.

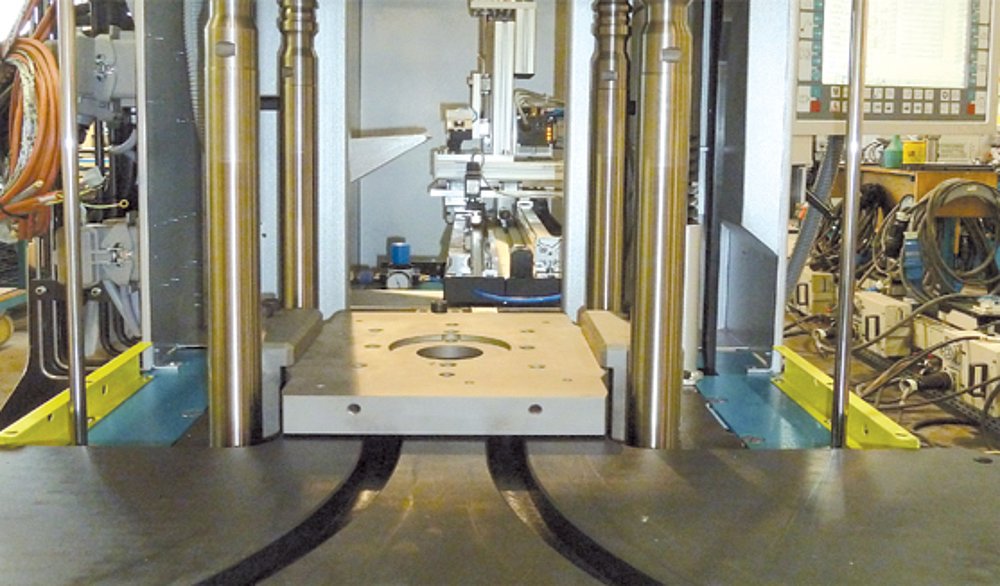

The lower platen is fixed. Therefore, a shifting of the insert parts during mould closing is excluded.

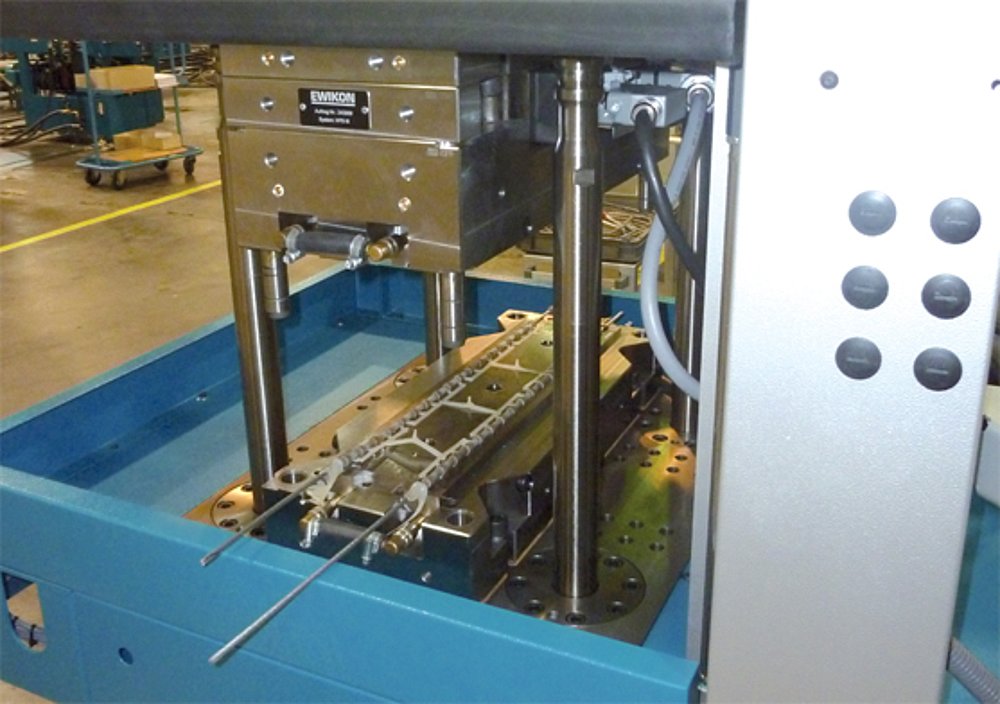

Shot weights of up to 69.5 g (PS) for highly precise applications, compact dimensions, ample space for peripheral equipment on the machine frame, as well as the possibility to also use smaller injection units make the BOY 35 E VV an ideal solution for fully automatic overmoulding of insert parts.

Facts

- Insert moulding machine

- compact design

- small footprint

- 350 kN clamping force

- Servo-Drive

- Two-Platen-clamping unit

- maximum efficiency

- maximum quality

- lower energy demand

- ideal for long term operation

- flexible use of moulds

- comfortable operation

- Procan ALPHA 6 control

- easy automation

- worldwide service

Specifications

| Euromap Size: 350-16 / 350-45 / 350-56 / 350-81 / 350-96 |

| Screw Diameter: 14, 18, 22, 24, 28, 32 mm |

| Max. Stroke Volume: 76.5 cm³ (theoretical) |

| Max. Injection Flow: 122.2 g/s (theoretical) |

| Max. Spec. Injection Pressure: 2739 bar |

| Max. Daylight Between Platen: 500 mm |

| Max. Opening Stroke: 300 mm |

| Distance Between Tie Bars: 280 x 254 mm |