BOY XS E - highly precise, highly economical, extremely compact

Injection moulding machine BOY XS E

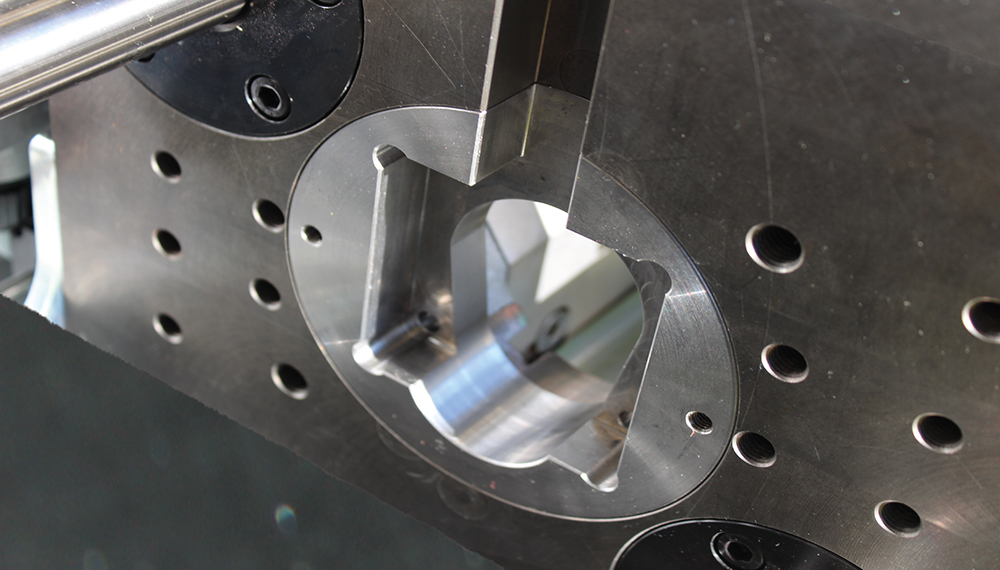

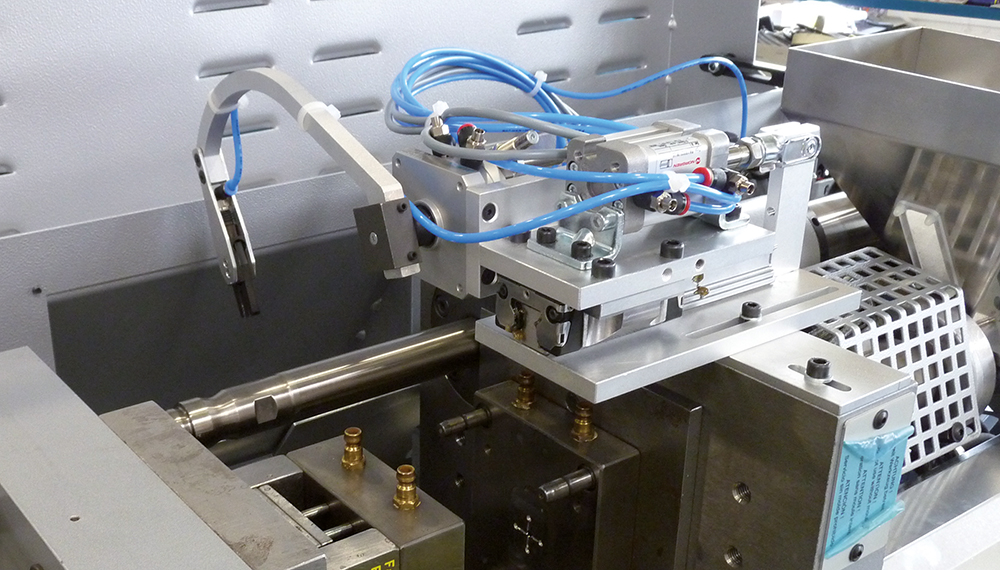

The cantilevered two-platen clamping unit of the BOY XS E with diagonal configuration of the tie bars makes the plasticising unit, the mould space and the ejector easily accessible and facilitates the integration of automation equipment. A special mould holder for micro moulds of many well-known standard mould manufacturers is optionally available for the BOY XS E.

With a clamping force of 100 kN on a floor space of 0.87 m², the BOY XS E offers a wide range of applications in the micro and sprueless small part injection moulding with innovative and proven technologies.

The BOY XS E is not equipped as common with this size injection moulding machines with a plunger type injection but with a reciprocating plasticizing screw with diameters from 8 to 18 mm working after the „first in first out“ principal and with a specific injection pressures up to 3128 bar. The intelligent design is ideally suited for the requirements of micro injection moulding.

The smallest injection unit of the BOY XS E with screw diameter of 8 mm assures shortest residence times – a great advantage for considerate processing of temperature-sensitive materials. The highly demanding production process with the 8 mm screw - which must always be considered in detail from application to application - requires the attention / compliance of the process-relevant injection moulding parameters.

Not only the screen format of the intuitive ALPHA 6 control has been changed to 16:9, but the more modern visualisation with new symbols and added functions ensure an absolute precision and repeatability with easy operability.

Facts

• Maximum performance in the smallest area

• Designed for continuous industrial operation

• More precise, most economical, extremely compact

• Intuitively operable and precise ALPHA 6 control

• Selectable two-platen configurations

• Injection unit that is height-adjustable by 25 mm (Option) guarantees a decentral gating

• Maximum energy efficiency

• Easily adaptable to automated processes and interface options for Industry 4.0

Specifications

| Euromap Size: 100-3 / 100-14 / 100-23 |

| Screw Diameter: 8, 12, 14, 16, 18 mm |

| Max. Stroke Volume: 15.3 cm³ (theoretical) |

| Max. Injection Flow: 46.3 g/s (theoretical) |

| Max. Spec. Injection Pressure: 3128 bar |

| Max. Daylight Between Platen: 250 mm |

| Max. Opening Stroke: 150 mm |

| Distance Between Tie Bars: 160 mm |