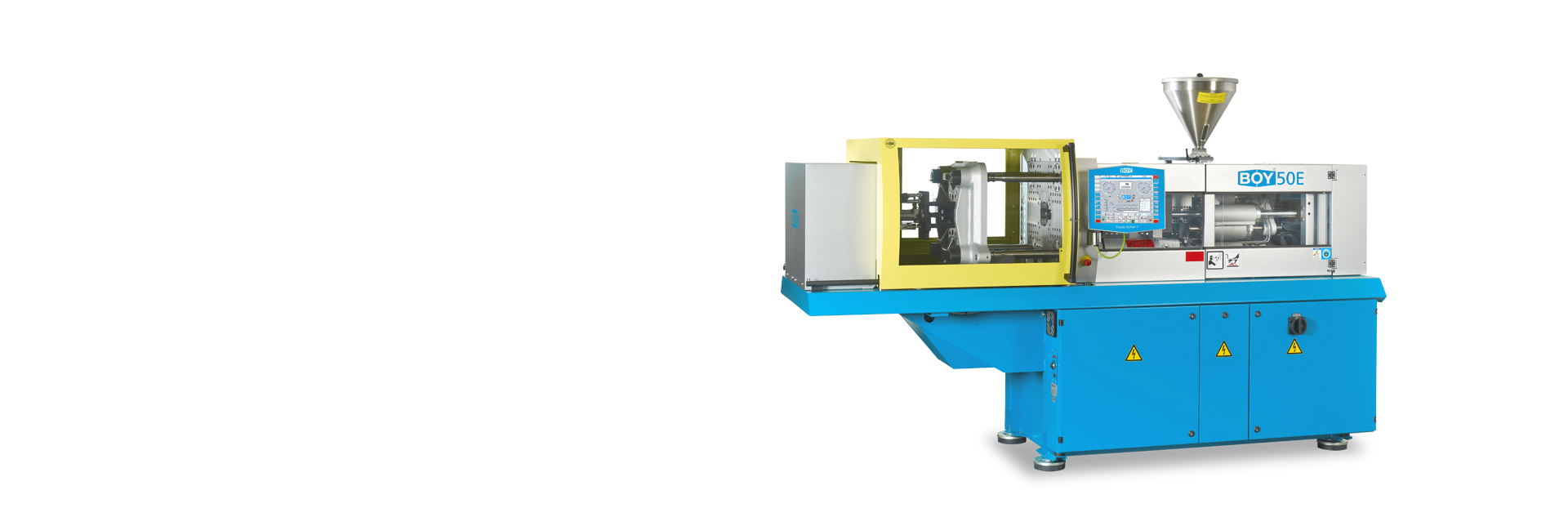

BOY 50 E – Powerful Injection Moulding Machine with 500 kN and Servo Drive

Precise, efficient, and ideal for all injection moulding processes

The BOY 50 E represents top-class performance among injection moulding machines, featuring 500 kN clamping force, a servo motor pump drive, and the proven Procan ALPHA 6 control system. Even in its standard configuration, it provides a wide range of functions for automated injection moulding, surpassing classic electro-mechanical technology in performance, efficiency, and precision.

Industry standards redefined

With its combination of high clamping force, compact design, and energy-efficient drive, the BOY 50 E sets new standards in plastics processing. It meets the highest demands for quality, cost-effectiveness, and flexibility, making it ideal for fully automated injection moulding in modern production environments.

Highlights

- Injection moulding machine

- compact design

- 500 kN clamping force

- Servo-Drive

- two-Platen-clamping unit

- maximum efficiency

- maximum quality

- lower energy demand

- maximum precision

- flexible use of moulds

- comfortable operation

- Procan ALPHA 6 control

- easy automation

- worldwide service

Technical data

- Euromap Size:

500-56 / 500-69 / 500-82 / 500-170 - Screw Diameter:

18, 22, 24, 28, 32, 38, 42 - Max. Stroke Volume:

173.2 cm³ (theoretical) - Injection Volume Flow:

207.8 cm³/s - Max. Spec. Injection Pressure:

2739 bar - Max. Daylight Between Platen:

650 mm - Max. Opening Stroke:

400 mm - Distance Between Tie Bars:

360 x 335 mm