Energy Saving – EconPlast Technology for Injection Moulding Machines

Future-proof plastics processing with maximum energy efficiency

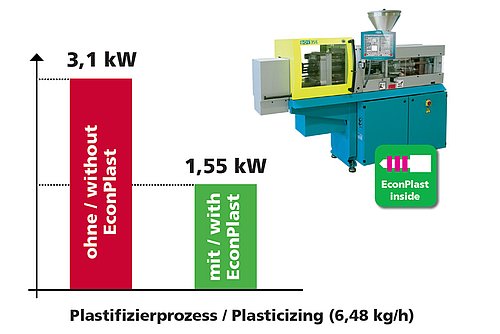

EconPlast units help users save up to 50% energy during plasticising, reducing operational costs while improving sustainability. This innovative technology not only cuts energy consumption but also shortens start-up and warm-up times, enhances temperature control, and minimises reject rates — a decisive advantage for cost-effective and eco-friendly injection moulding.

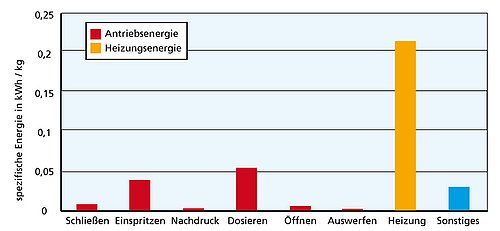

Energy consumption in injection moulding – where the greatest potential lies

Plasticising (melting the material) is the most energy-intensive step in injection moulding. Cylinder heating and dosing account for the largest share of energy use. EconPlast technology targets these areas, achieving significant savings.

Energy consumption of an injection molding machine (Source: Kunststoffe 2/2012)

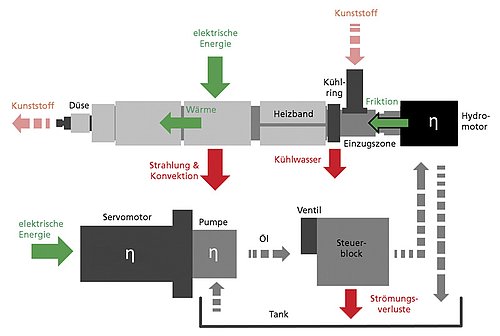

Plasticising occurs through electric heating bands and frictional heat generated by the screw, which is hydraulically driven via a servo motor pump drive. Energy losses typically occur at the motor, pump, hydraulic motor, and due to flow resistance.

Schematic representation of the plasticizing process

Improved energy balance with EconPlast

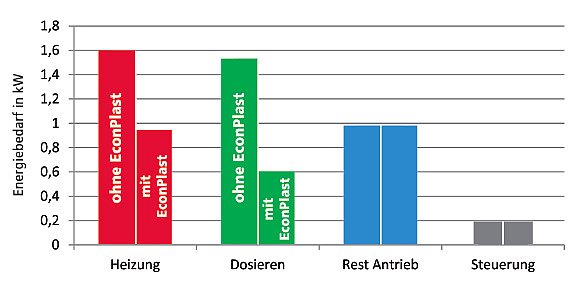

Comparative tests show up to 40% energy savings during heating and up to 60% during dosing with EconPlast.

Key Advantages:

- Up to 40% less energy for heating

- Around 60% energy savings during dosing

- Faster, more precise temperature control

- Shorter start-up and warm-up times

- Lower reject rate through material-friendly processing

- Longer service life with wear-resistant plasticising units

- Improved feed zone cooling and optimised material homogeneity

- Optional for all injection moulding machines with screw diameters ≥18 mm