Micro injection moulding – high-precision plastics processing for the smallest parts

Maximum precision with minimal shot weight

BOY injection moulding machines allow the economical production of extremely small plastic parts. The 8 mm screw-piston plasticising unit ensures short dwell times, gentle material handling, and outstanding part quality – perfect for micro injection moulding and sensitive materials like PBT.

Efficiency & innovation for miniature components

Our patented plasticising unit with a barrel volume of only 1.9 cm³ reduces residence times by over 75% compared to 12 mm screws and over 80% compared to 14 mm screws. The first-in-first-out principle and minimal pre-plasticising guarantee, optimal processing of thermally sensitive materials.

Wide-ranging applications & expertise

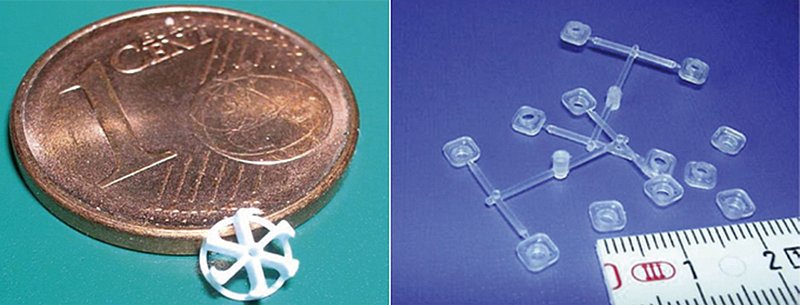

BOY machines are proven in medical technology, automotive, electronics, optics and microfluidics. from micro-osteosynthesis plates of 0.06 cm³ (approx. 0.078 g) to full-scale series production, BOY stands for precision, efficiency, and uncompromising quality