Overmoulding & Insertion – precision, automation, flawless surfacese

Automated overmoulding at the highest level

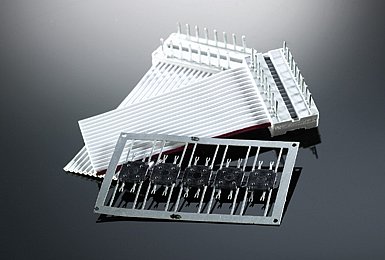

For decades, BOY has been setting standards in overmoulding technology. Our injection moulding machines process inserts both horizontally and vertically with clamping forces from 100–600 kN. Thanks to a fixed lower platen and two-platen clamping unit, inserts remain securely in place, ensuring maximum precision and repeatability.

Advanced technology for demanding applications

Equipped with an energy-efficient control pump system, the intuitive Procan ALPHA control, and optional horizontal injection units (BOY 25 E VH and BOY 35 E VH), our machines enable lateral gating of central cavities. The result: surfaces free of visible gate marks – ideal for automatic insert moulding where aesthetics and quality matter most.

Benefits & versatile applications

BOY overmoulding technology is perfectly suited for applications requiring metal or plastic inserts – from visible surfaces and optical components to technical precision parts. Manufacturers worldwide rely on BOY for consistent quality, high performance, and flawless results.