Thermoset process – heat-resistant & insulating injection moulding solutions with BOY

High performance for extreme requirements

Technical equipment & process reliability

BOY machines feature liquid-tempered cylinders controlled via an external unit, feed screws without backflow prevention, and optional embossing and ventilation programs. Standard models—including BOY 25, 35, 50, 60, 80, 100, and 125—integrate internal control circuits for precise mould temperature management, complemented by electric heating elements. Brushing programs for mould cleaning further enhance product quality and ensure long-term durability.

Applications & industry diversity

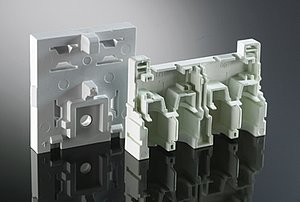

From coil bodies and fuse housings to belt tensioners, BOY injection moulding machines use thermoset processes to produce high-security parts for electrical engineering, the automotive industry, and general mechanical engineering. The combination of process reliability, insulation, and durability makes BOY thermoset solutions indispensable for demanding applications in plastics processing.