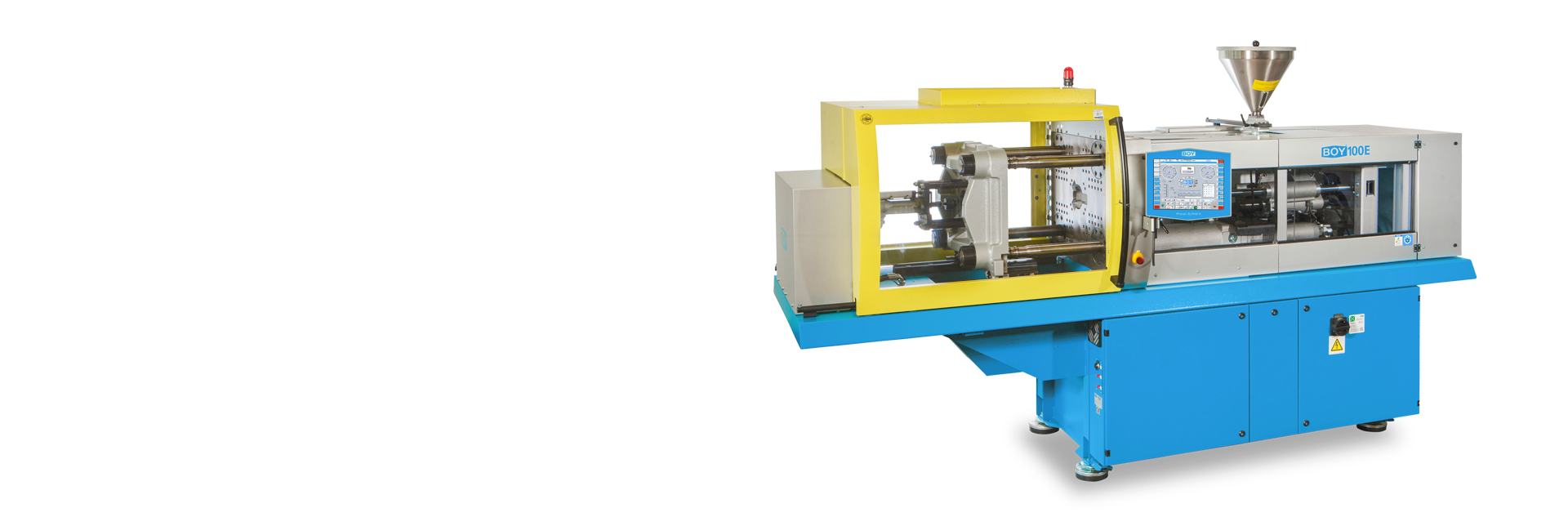

BOY 100 E – High-Precision Injection Moulding Machine with 1000 kN

Energy efficiency and automation at the highest level

The BOY 100 E is the most powerful machine in the E series. With 1000 kN clamping force, an energy-efficient servo motor drive, and the Procan ALPHA 6 control system, it sets new benchmarks in dynamics, precision, and automation. Even in its standard configuration, it is ready for fully automated injection moulding.

Compact, precise and extremely flexible

Despite its power, the BOY 100 E remains compact and ergonomic. The two-platen clamping system, energy-optimised design, and generous mould access ensure flexibility. With screw diameters of 28–52 mm, a displacement up to 339 cm³, and injection pressures up to 2,798 bar, it delivers consistent high-quality results in modern plastics processing.

Highlights

- Injection moulding machine

- 1000 kN clamping force

- Servo-Drive

- moveable injection unit

- Two-Platen-clamping unit

- maximum efficiency

- maximum quality

- lower energy demand

- maximum precision

- flexible use of moulds

- comfortable operation

- Procan ALPHA 6 control

- easy automation

- worldwide service

Technical data

- Euromap Size:

1000-215 / 1000-220 / 1000-400 - Screw Diameter:

36 ,38, 42, 48, 52 mm - Max. Stroke Volume:

339.8 cm³ (theoretical) - Injection Volume Flow:

339.8 cm³/s - Max. Spec. Injection Pressure:

2798 bar - Max. Daylight Between Platen:

725 mm - Max. Opening Stroke:

475 mm - Distance Between Tie Bars:

430 x 360 mm