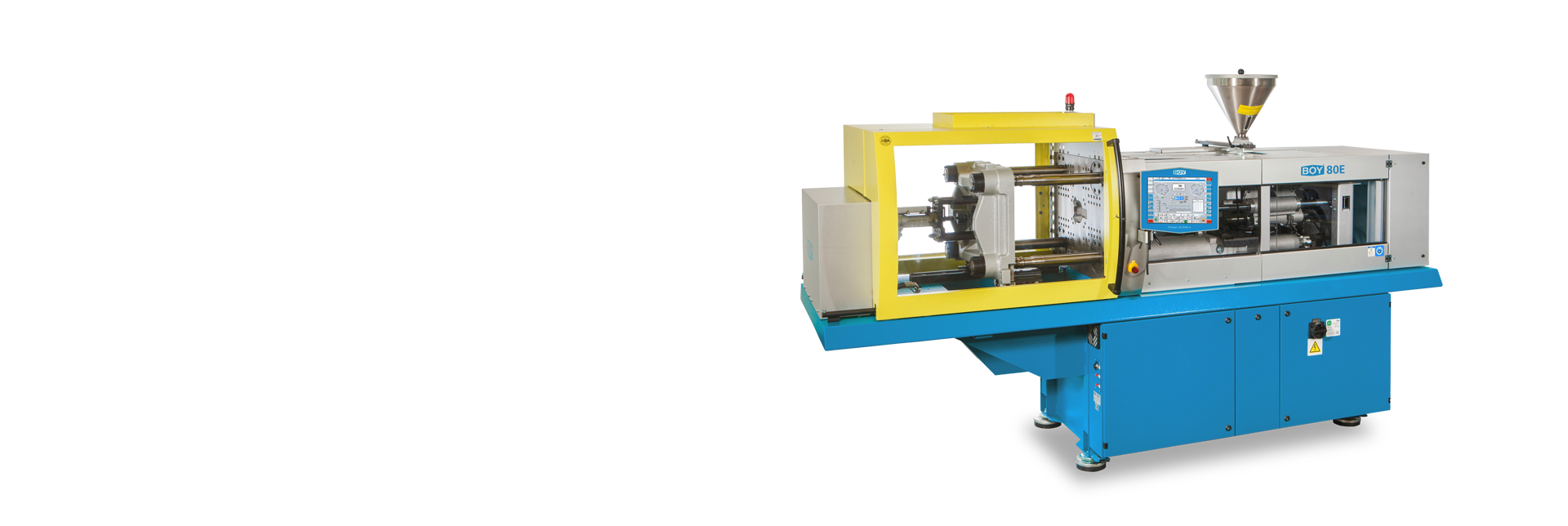

BOY 80 E – Powerful Injection Moulding Machine for Energy-Efficient Precision

Top performance with servo drive and automation potential

The BOY 80 E is a high-performance injection moulding machine with 800 kN clamping force, a servo motor pump drive, and the integrated Procan ALPHA 6 control system. It surpasses traditional electromechanical machines in efficiency, dynamics, and overall cost-effectiveness. Even in its standard configuration, it is fully automatable and ideal for modern injection moulding automation.

Compact, precise, and versatile

Combining a robust two-platen clamping system with energy-efficient technology, the BOY 80 E delivers maximum precision, repeat accuracy, and process reliability. Screw diameters from 28–42 mm, a displacement of up to 173 cm³, and injection pressures up to 2,798 bar ensure versatile tool use and consistent high-quality results in plastics processing.

Highlights

- Injection moulding machine

- compact design

- 800 kN clamping force

- Servo-Drive

- two-Platen-clamping unit

- maximum efficiency

- maximum quality

- lower energy demand

- maximum precision

- flexible use of moulds

- comfortable operation

- Procan ALPHA 6 control

- easy automation

- worldwide service

Technical data

- Euromap Size:

800-215 - Screw Diameter:

28, 32, 38, 42 - Max. Stroke Volume:

173.2 cm³ (theoretical) - Injection Volume Flow:

333.5 cm³/s - Max. Spec. Injection Pressure:

2798 bar - Max. Daylight Between Platen:

725 mm - Max. Opening Stroke:

475 mm - Distance Between Tie Bars:

430 x 360 mm