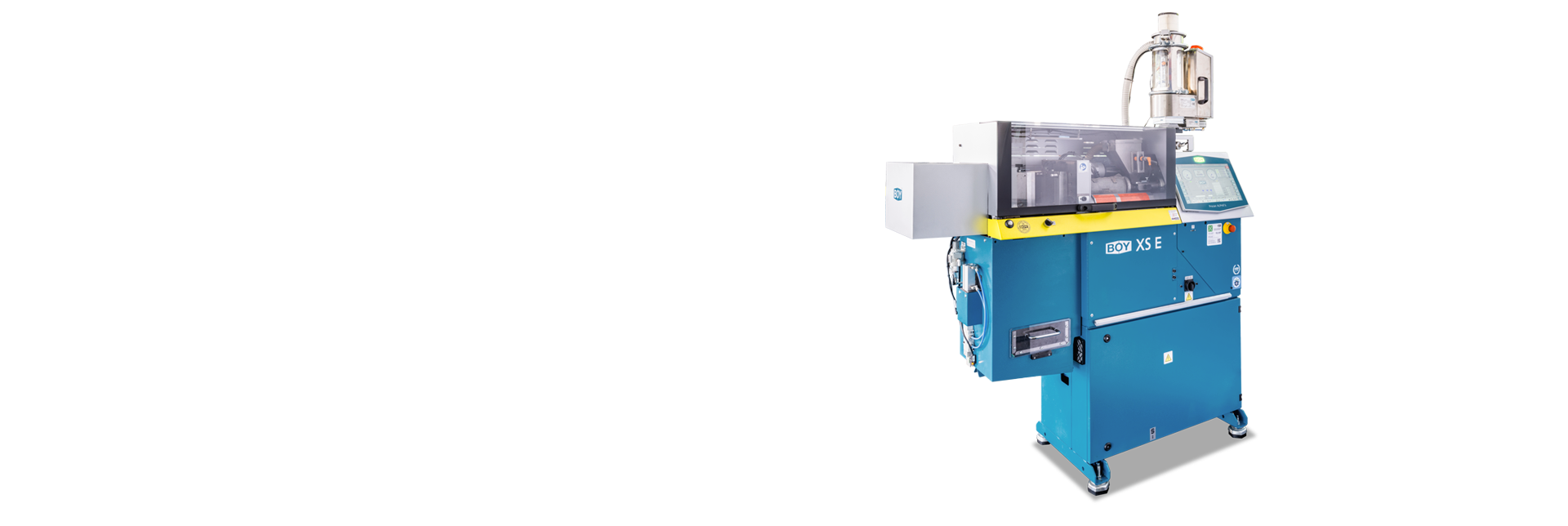

BOY XS E – Ultra-Compact Injection Moulding Machine for Micro Injection Moulding and Automation

Precise, economical, and fully automatable

The BOY XS E combines extremely compact design with high precision. With 100 kN clamping force on just 0.87 m², it delivers innovative solutions for micro injection moulding and sprue-free small parts production. The freely protruding two-platen clamping unit with diagonal tie bars provides excellent access to the plasticising unit, mould chamber, and ejector — ideal for automation. Optional special clamping plates are available for micro moulds from leading standard parts manufacturers.

State-of-the-art plasticising & material protection

The screw plasticising unit (Ø 8–18 mm), designed according to the first-in, first-out principle, delivers injection pressures up to 3,128 bar with minimal dwell times. This ensures gentle handling of sensitive plastics, particularly with the 8 mm unit, making the XS E perfect for demanding micro injection moulding applications.

Ease of use & Industry 4.0 capability

The ALPHA 6 control system with a large 16:9 display provides modern visualisation, advanced symbols, and functions for high process precision and repeatability. BOY sets new standards in energy efficiency, user-friendliness, and Industry 4.0 integration.

Highlights

- Maximum performance in the smallest area

- Designed for continuous industrial operation

- More precise, most economical, extremely compact

- Intuitively operable and precise ALPHA 6 control

- Selectable two-platen configurations

- Injection unit that is height-adjustable by 25 mm (Option) guarantees a decentral gating

- Maximum energy efficiency

- Easily adaptable to automated processes and interface options for Industry 4.0

Technical data

- Euromap Size:

100-3 / 100-14 / 100-23 - Screw Diameter:

8, 12, 14, 16, 18 mm - Max. Stroke Volume:

15.3 cm³ (theoretical) - Injection volume Flow:

50.9 cm³/s - Max. Spec. Injection Pressure:

3128 bar - Max. Daylight Between Platen:

250 mm - Max. Opening Stroke:

150 mm - Distance Between Tie Bars:

160 mm