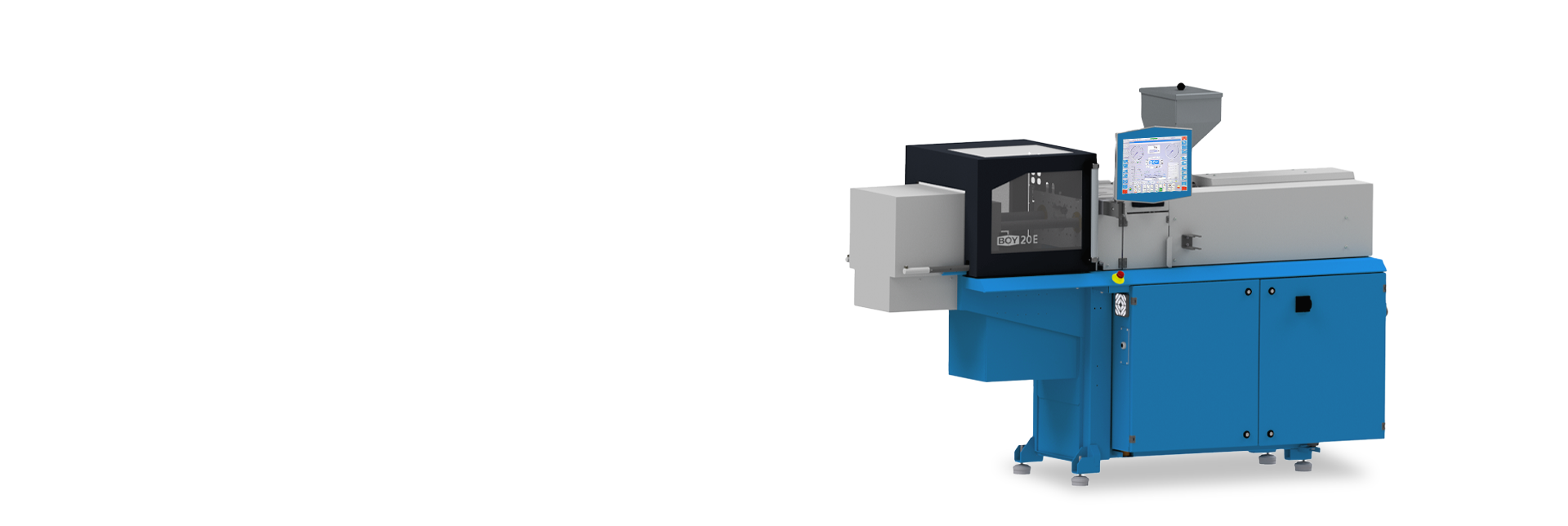

BOY 20 E PRO – Compact Injection Moulding Machine with Maximum Efficiency

Reliability & Low Operating Costs

The BOY 20 E PRO impresses with outstanding reliability and extremely low hourly machine rates. With a footprint of only 1.8 m², it is one of the most compact injection moulding machines on the market while offering maximum efficiency in plastics processing.

Ergonomic Design & Flexible Expansion

The free-standing clamping unit provides optimal accessibility and can be individually expanded with automation equipment. Its simple, clear, and ergonomic design ensures ease of operation and process reliability – ideal for automation in injection moulding.

Versatility with Injection Units & Options

In addition to injection units 11 and 15, the SP 52 injection unit with seven different screw diameters offers a wide range of applications. The performance spectrum of the BOY 20 E PRO is further enhanced by numerous options – from integrated handling interfaces with Integralpicker to standardized interfaces such as EUROMAP 67. This makes the BOY 20 E PRO a future-proof injection moulding machine for a wide variety of applications.

Highlights

- Compact design (only 1.8 m² footprint)

- 200 kN clamping force

- Two-platen clamping unit

- Maximum efficiency & quality

- Lower energy demand

- Flexible use of moulds

- komfortable operation

- Cutting-edge technology – at a low price

- State-of-the-art control system

- Entry into energy-efficient servo-motor pump drives

- Attractive price-performance ratio

- Robust, proven design

- High cost-effectiveness thanks to low hourly machine rates

- Generous mold mounting dimensions with additional fastening options

Technical data

- Euromap Size:

200-11 / 200-15 / 200-52 - Screw Diameter:

12, 14, 18, 22, 24, 28, 32 - Max. Stroke Volume:

64.3 cm³ (theoretical) - Injection Volume Flow:

114.2 cm³/s - Max. Spec. Injection Pressure:

2587 bar - Max. Daylight Between Platen:

400 mm - Max. Opening Stroke:

200 mm - Distance Between Tie Bars:

254 mm