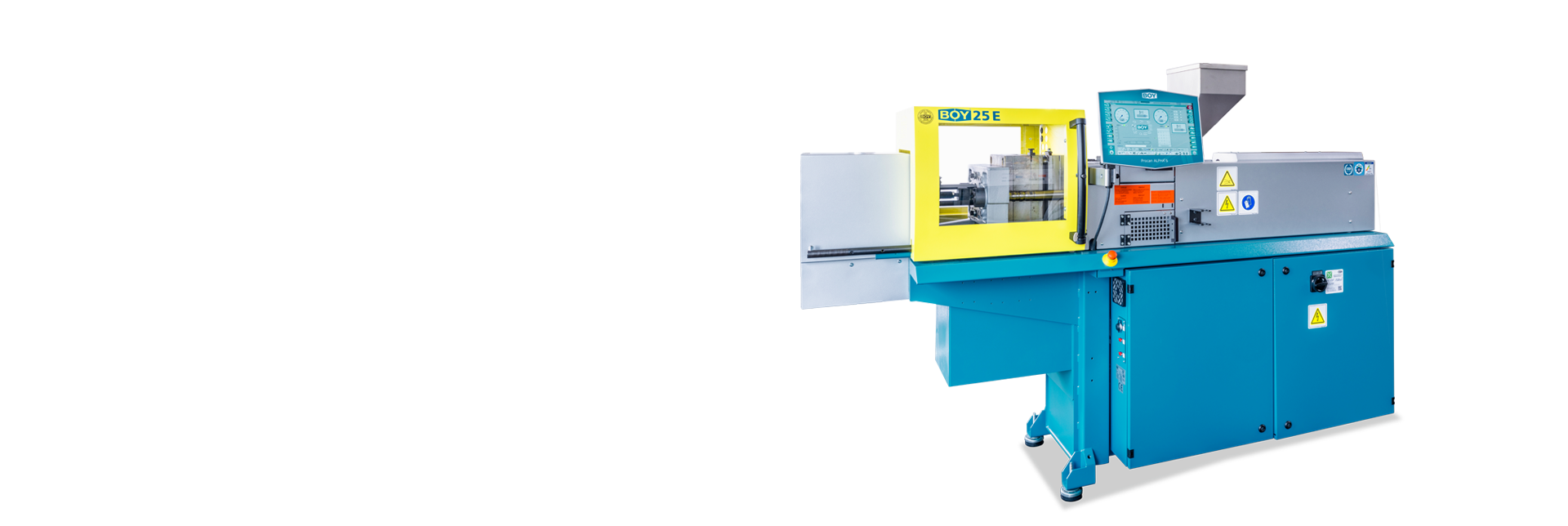

BOY 25 E – Compact Injection Moulding Machine with 250 kN for Automated Injection Moulding

Efficiency and precision for plastics processing

BOY stands for advanced technology and high machine availability. The BOY 25 E combines 250 kN clamping force with differential injection for faster cycles and improved dynamics — ideal for automation and economical plastics processing.

Compact, accessible, and flexible

With a footprint of just 1.80 m², the BOY 25 E is one of the most compact machines in its class. The free-standing clamping unit simplifies mould changes and integration with handling systems. Six injection units and seven screw diameters provide full configurability, from micro to standard injection moulding, making the 25 E a versatile solution in the BOY portfolio.

Highlights

- Injection moulding machine

- compact design

- only 2.1 m² footprint

- 250 kN clamping force

- Servo-drive for BOY 25 E

- hydraulic drive

- two-Platen-clamping unit

- maximum efficiency

- maximum quality

- lower energy demand

- ideal for long term operation

- flexible use of moulds

- comfortable operation

- Procan ALPHA 6 control

- easy automation

- worldwide service

Technical data

- Euromap Size:

250-11 / 250-16 / 250-39 / 250-56 / 250-69 / 250-82 - Screw Diameter:

12, 14, 18, 22, 24, 28, 32 - Max. Stroke Volume:

76.5 cm³ (theoretical) - Injection Volume Flow:

122.2 cm³/s - Max. Spec. Injection Pressure:

2739 bar - Max. Daylight Between Platen:

400 mm - Max. Opening Stroke:

200 mm - Distance Between Tie Bars:

254 mm