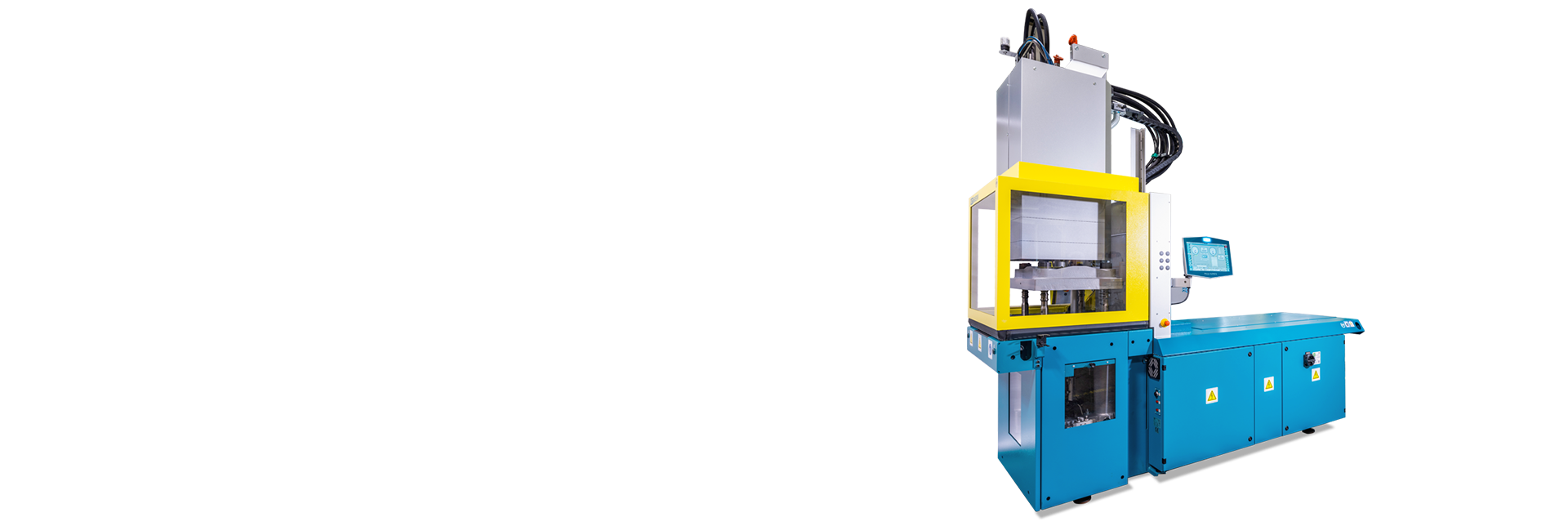

BOY 60 E VV – Powerful Vertical Injection Moulding Machine for Efficient Plastics Processing

Overmoulding with large volumes

The BOY 60 E VV delivers high productivity with 600 kN clamping force, perfect for manufacturers seeking precise, automated production. Its vertical design, large tie bars, and generous mould space provide optimal conditions for automated injection moulding and versatile mould usage.

Generous shot volume & compact design

Equipped with four screw diameters, the BOY 60 E VV handles large shot volumes and a wide variety of plastics applications. Despite its power, the machine remains compact for flexible space requirements and ensures low operating costs through efficient performance.

Highlights

- Insert moulding machine

- ergonomic construction

- compact design

- small footprint

- 600 kN clamping force

- hydraulic drive

- Two-Platen-clamping unit

- maximum efficiency

- maximum quality

- lower energy demand

- ideal for long term operation

- flexible use of moulds

- comfortable operation

- Procan ALPHA 6 control

- easy automation

- worldwide service

Technical data

- Euromap Size:

600-56 / 600-69 / 600-82 / 600-215 - Screw Diameter:

18, 22, 24, 28, 32, 38, 42 mm - Max. Stroke Volume:

173.2 cm³ (theoretical) - Injection Volume Flow:

207.8 cm³/s - Max. Spec. Injection Pressure:

2798 bar - Max. Daylight Between Platen:

550 mm - Max. Opening Stroke:

300 mm - Distance Between Tie Bars:

360 x 335 mm