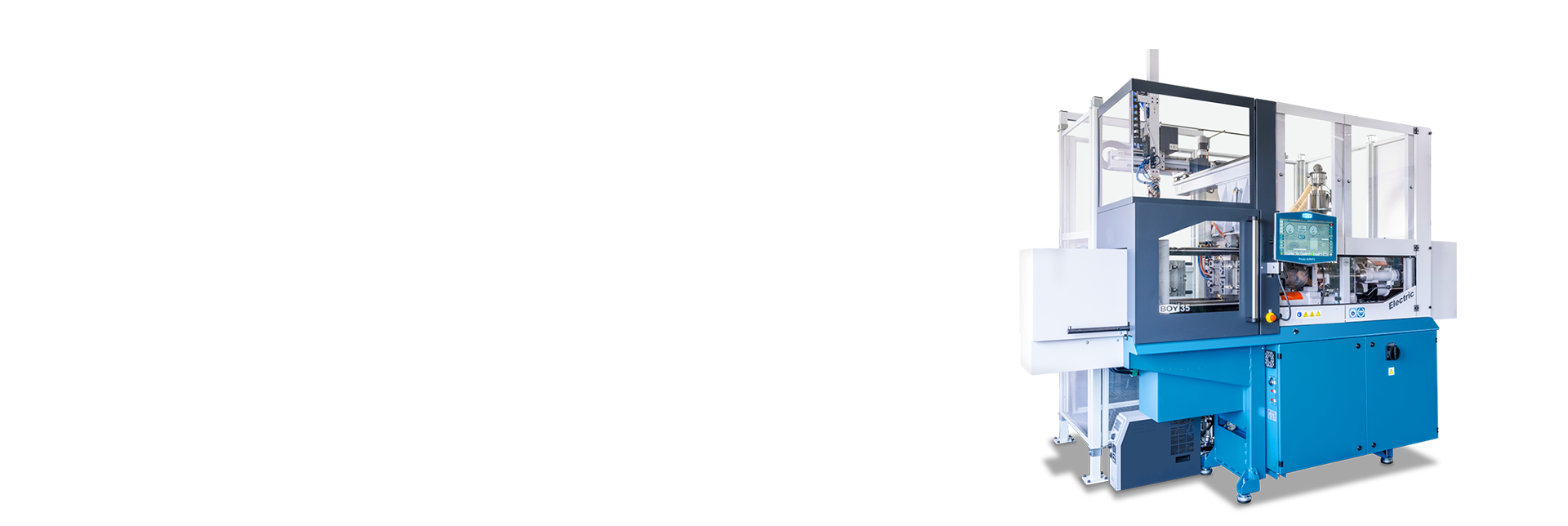

BOY 35 E VV – Vertical Injection Moulding Machine for Automated Plastics Processing

Vertical precision & compact dimensions

The BOY 35 E VV combines high-performance injection moulding with a vertical two-platen clamping system, mirroring the proven design of the horizontal BOY 35 E. Its vertical arrangement maximises ergonomics and mould accessibility. The fixed lower clamping plate prevents inserts from slipping, ensuring top precision in insert overmoulding.

Compact, efficient & flexible

With 350 kN clamping force and technically advanced design, the BOY 35 E VV is ideal for automated plastics processing. Shot weights up to 69.5 g enable high precision across diverse applications. Compact dimensions and generous space for peripheral equipment make it the perfect choice for flexible, cost-effective production.

Highlights

- Insert moulding machine

- compact design

- small footprint

- 350 kN clamping force

- Servo-Drive

- Two-Platen-clamping unit

- maximum efficiency

- maximum quality

- lower energy demand

- ideal for long term operation

- flexible use of moulds

- comfortable operation

- Procan ALPHA 6 control

- easy automation

- worldwide service

Technical data

- Euromap Size:

350-16 / 350-45 / 350-56 / 350-81 / 350-96 - Screw Diameter:

14, 18, 22, 24, 28, 32 mm - Max. Stroke Volume:

76.5 cm³ (theoretical) - Injection Volume Flow:

134.3 cm³/s - Max. Spec. Injection Pressure:

2739 bar - Max. Daylight Between Platen:

500 mm - Max. Opening Stroke:

300 mm - Distance Between Tie Bars:

280 x 254 mm