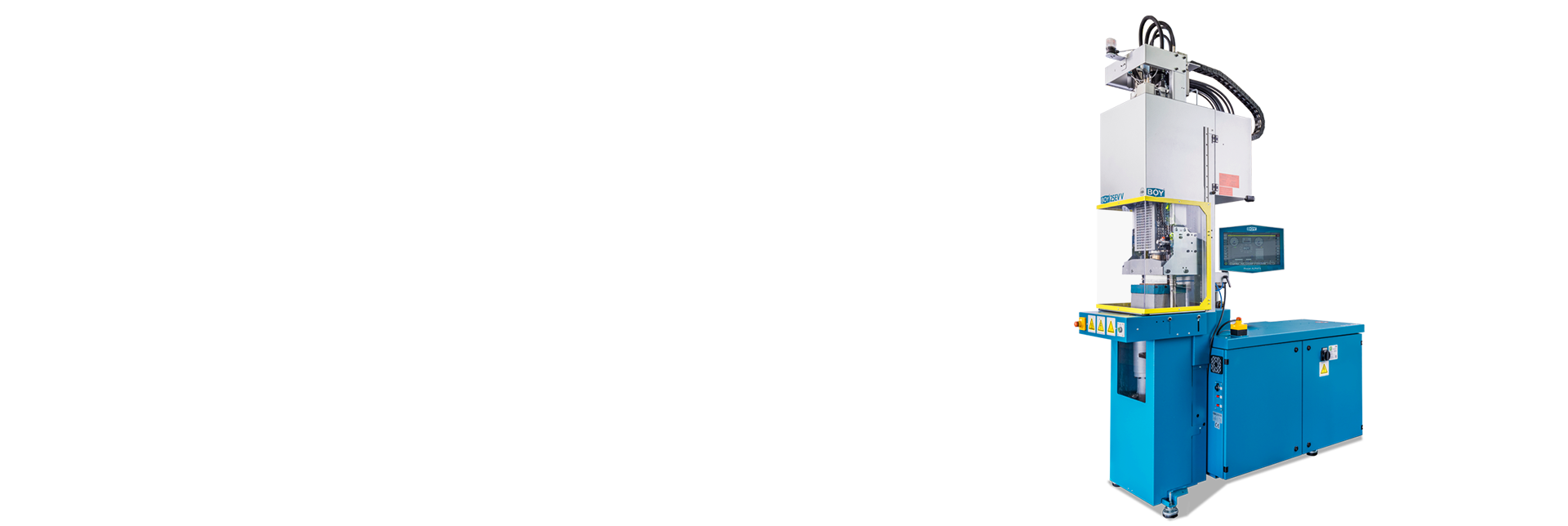

BOY 25 E VV – Vertical Overmoulding Machine with 250 kN for High-Quality Plastics Processing

Maximum precision & compact efficiency

The BOY 25 E VV is a proven injection moulding machine that combines 250 kN clamping force with a vertical two-platen clamping system. Its fixed base and approximately 11% smaller footprint ensure ergonomic, safe access to the moulding chamber — ideal for automated overmoulding production.

Advanced hydraulics & rapid cycles

Equipped with a new hydraulic pump delivering higher flow, the BOY 25 E VV enables faster machine movements. Optimised flow control and low friction reduce dry running times to just over one second (per EUROMAP 6), achieving maximum energy efficiency while maintaining peak performance.

Highlights

- Insert moulding machine

- clamping and injection units vertically arranged

- compact design

- only 1,40 m² footprint

- 250 kN clamping force

- hydraulic drive

- Two-Platen-clamping unit

- maximum efficiency

- maximum quality

- lower energy demand

- ideal for long term operation

- flexible use of moulds

- comfortable operation

- Procan ALPHA 6 control

- easy automation

- worldwide service

Technical data

- Euromap Size:

250-11 / 250-16 / 250-39 / 250-56 / 250-69 / 250-82 - Screw Diameter:

12, 14, 18, 22, 24, 28, 32 mm - Max. Stroke Volume:

76.4 cm³ (theoretical) - Injection Volume Flow:

122.2 cm³/s - Max. Spec. Injection Pressure:

2739 bar - Max. Daylight Between Platen:

400 mm - Max. Opening Stroke:

200 mm - Distance Between Tie Bars:

254 mm