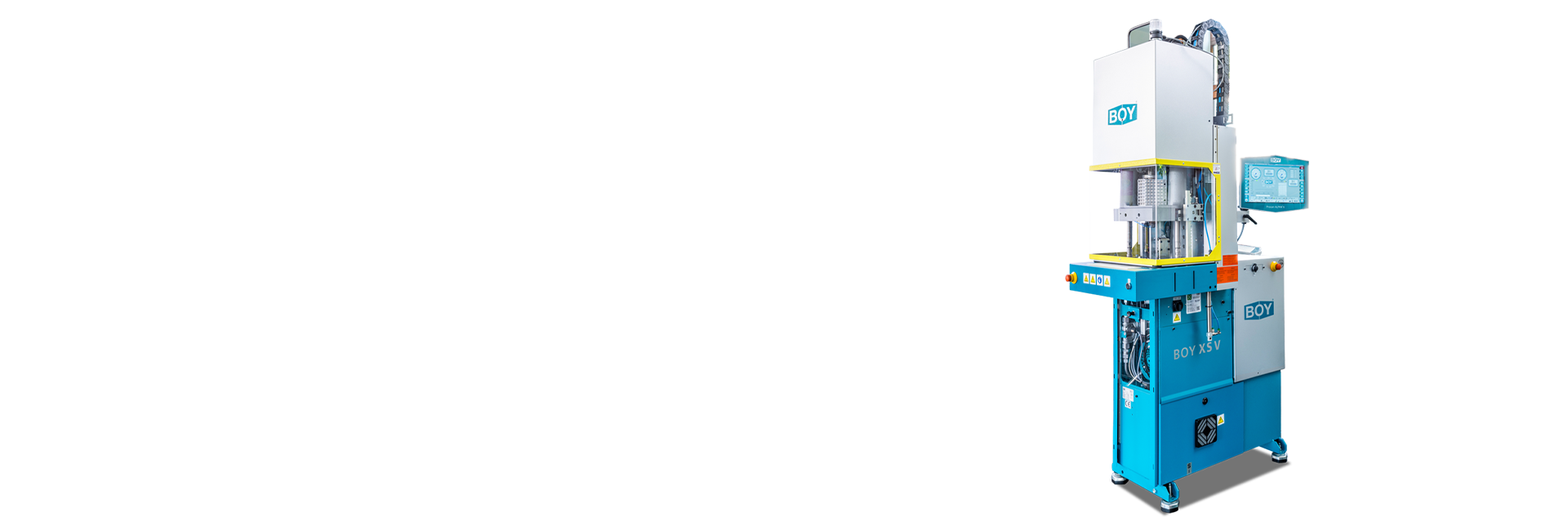

BOY XS V – Vertical Injection Moulding Machine for Automated Overmoulding

Smallest BOY overmoulding machine for precise results

The BOY XS V is a compact vertical injection moulding machine featuring a vertical injection and clamping system. Ideal for overmoulding metal parts, semi-finished components, or cable ends, its fixed lower clamping unit prevents slippage during mould closure — essential for high-precision injection moulding.

Flexibility, automation & integration

With a two-platen clamping system and diagonally arranged tie bars, the BOY XS V offers excellent accessibility from all sides and seamless integration into automated production lines.

Highlights

- Insert moulding machine

- clamping and injection units vertically arranged

- ultra-compact

- only 0,69 m² footpring

- 100 kN clamping force

- perfect for Micro-injection

- maximum efficiency

- lower energy demand

- ideal for long term operation

- flexible use of moulds

- comfortable operation

- Procan ALPHA 4 control

- easy automation

- worldwide service

Technical data

- Euromap Size:

100-3 / 100-14 / 100-23 - Screw Diameter:

8, 12, 14, 16 mm - Max. Stroke Volume:

8.0 cm³ (theoretical) - Injection Volume Flow:

50.9 cm³/s - Max. Spec. Injection Pressure:

3128 bar - Max. Daylight Between Platen:

250 mm - Max. Opening Stroke:

150 mm - Distance Between Tie Bars:

160 mm