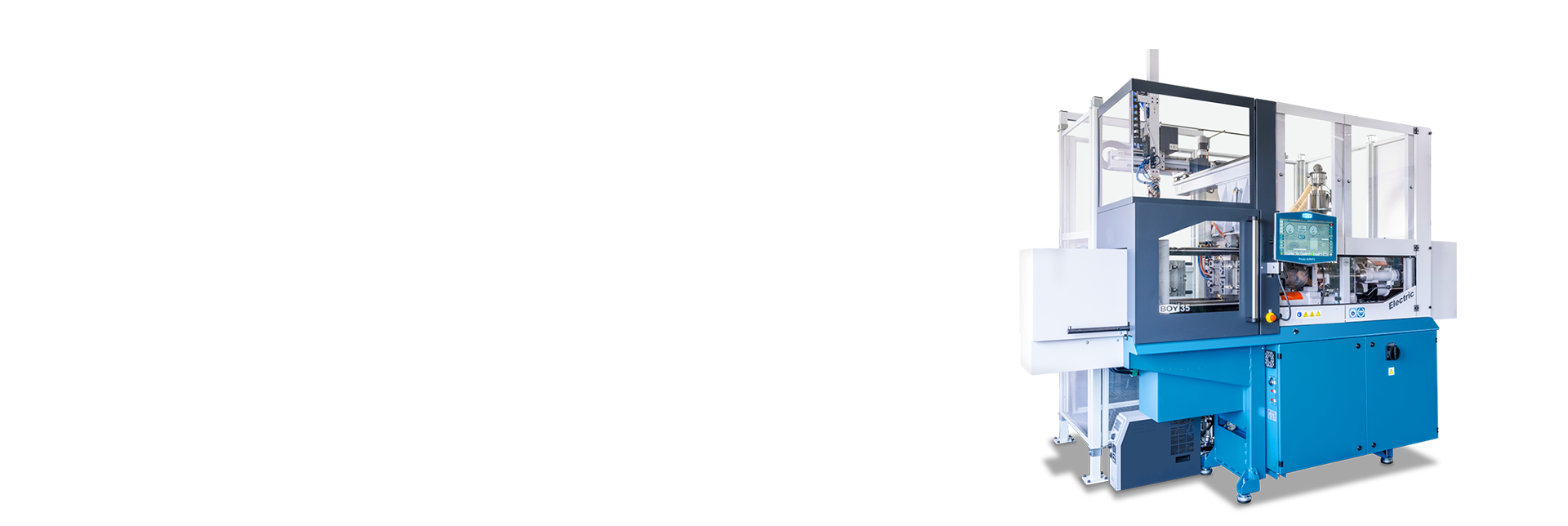

BOY 35 Electric – fully electric injection moulding machine for dynamics and automation

State-of-the-art technology meets efficiency in injection moulding

The BOY 35 Electric is a fully electric injection moulding machine featuring electromechanical drives for injection, dosing, and ejection. With outstanding dynamics, precise position detection, and shorter cycle times, it is the ideal solution for automated, modern plastics processing.

Compact design & energy-efficient innovation

The injection moulding machine is equipped with a newly developed universal injection unit featuring patented back pressure measurement. Its two-platen clamping unit, oil- and lubricant-free mould area, servo hydraulics, pressure intensifier, and differential pressure technology all contribute to exceptional energy efficiency. The electromechanical ejector delivers precise, highly dynamic movements—without stick-slip—both at full load and during slow operations. With its redesigned compact safety technology (OSSD), the machine maintains a small footprint without compromising performance.

Highlights

- Parallel movement without double pump

- Compactness of a two-platen machine

- Highly dynamic injection unit

- Lubricant-free tool installation area

- Improved synchronised movement during ejection

- Parallel clamping force build-up for injection

- Highest positioning accuracy

- Possibility to actively brake

Technical data

- Euromap Size:

350-11 / 350-16 / 350-45 / 350-56 / 350-81 / 350-96 - Screw Diameter:

12, 14, 18, 22, 24, 28, 32 - Max. Stroke Volume:

76.5 cm³ (theoretisch) - Max. Injection Flow:

134.3 cm³/s - Max. Spec. Injection Pressure:

2655 bar - Max. Daylight Between Platen:

500 mm - Max. Opening Stroke:

300 mm - Distance Between Tie Bars:

280 x 254 mm