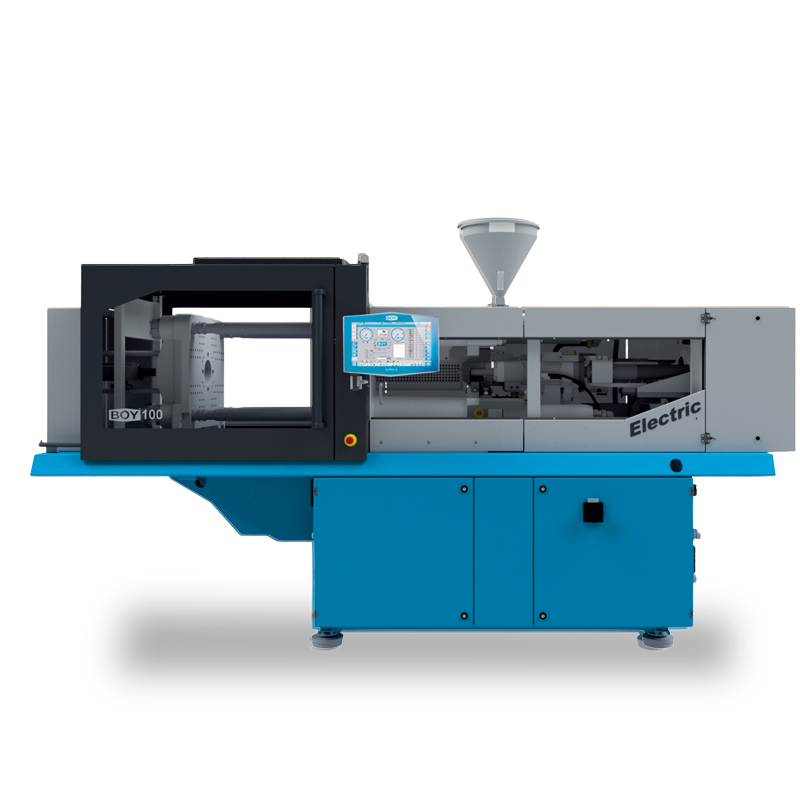

Electromechanical Injection Moulding Machines

Precision, Dynamics & Shorter Cycle Times

With the new BOY Electric series (350–1000 kN clamping force), BOY expands its portfolio with fully electric injection moulding machines – as an alternative to the proven, energy-saving servo-hydraulic machines of the E series.

Advantages of the BOY Electric

- High dynamics & parallel movements thanks to electromechanical drives for injection, plasticizing, and ejection

- Patented back pressure measurement: direct force transmission via force sensor for maximum process accuracy

- Two-platen clamping unit with oil- and lubricant-free mould area, combined with energy-efficient servo hydraulics

- New electromechanical ejector: precise, highly dynamic, stick-slip free – saves cycle time and protects mould & machine

- Compact design with integrated drive and inverter technology

- Modern safety technology (OSSD) for maximum operational safety with minimal footprint

BOY 35 Electric

In addition to the proven and energy-saving servo-hydraulic machines of the well-established E-Series, our portfolio now also includes the BOY Electric series, covering the clamping force range from 350 to 800 kN.

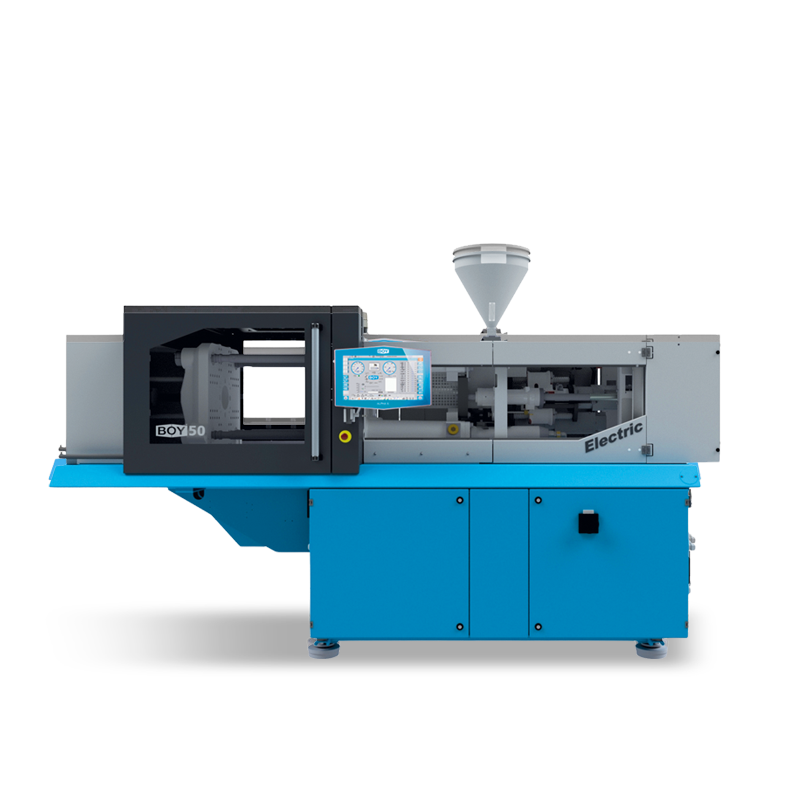

BOY 50 Electric

In addition to the proven and energy-efficient servo-hydraulic machines of the established E-Series, our portfolio now also includes the BOY Electric Series with a clamping force range of 350 – 800 kN.

BOY 80 Electric

In addition to the proven and energy-efficient servo-hydraulic machines of the established E-series, the BOY Electric series with clamping forces ranging from 350 to 800 kN is now also part of our portfolio.