The alternative in the additive manufacturing

3D-printed metal tool inserts impose higher demands on mould design

If only small batches of a plastic part are required or if the component is still in the development phase, modern 3D-technology can help to save mould costs. Instead of the complex construction of expensive steel moulds, more flexible and cost-efficient solutions are required, especially in prototype construction and in the increasingly individualized design of components.

Direct or indirect

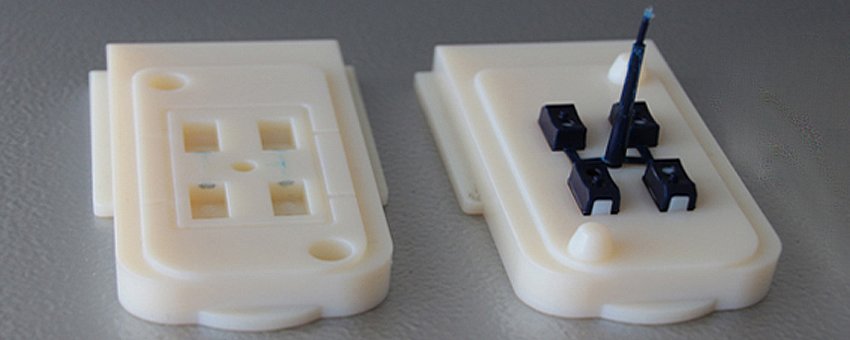

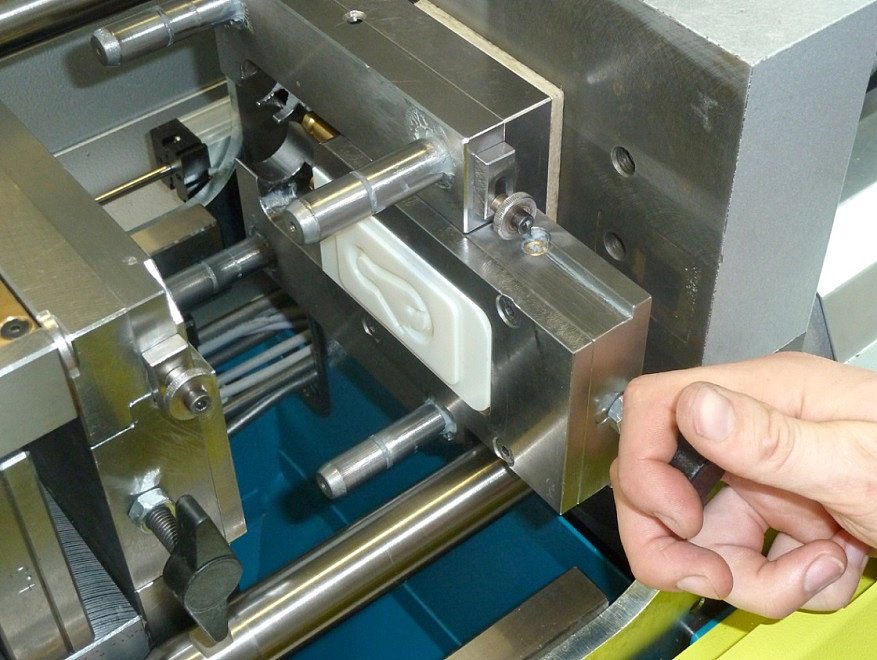

However, a direct part production from the 3D-printer differs significantly from an injection moulded part. For example, the physical properties of a 3D-printed component of injection-moulded parts are sometimes significantly different. The solution is 3D-printed mould inserts (installed in a cassette mould), which can be used for a very cost-effectively production of plastic parts.

Based on the CAD data of the plastic part, the print data of the mould inserts can be prepared accordingly and 3D-printers create the mould. Depending on the size of the components, this can already be done within minutes, for larger designs longer processing times are required. Nevertheless, these mould inserts are prepared much faster and cheaper than their “steel competitors”.

From the plastic mould to the metal mould

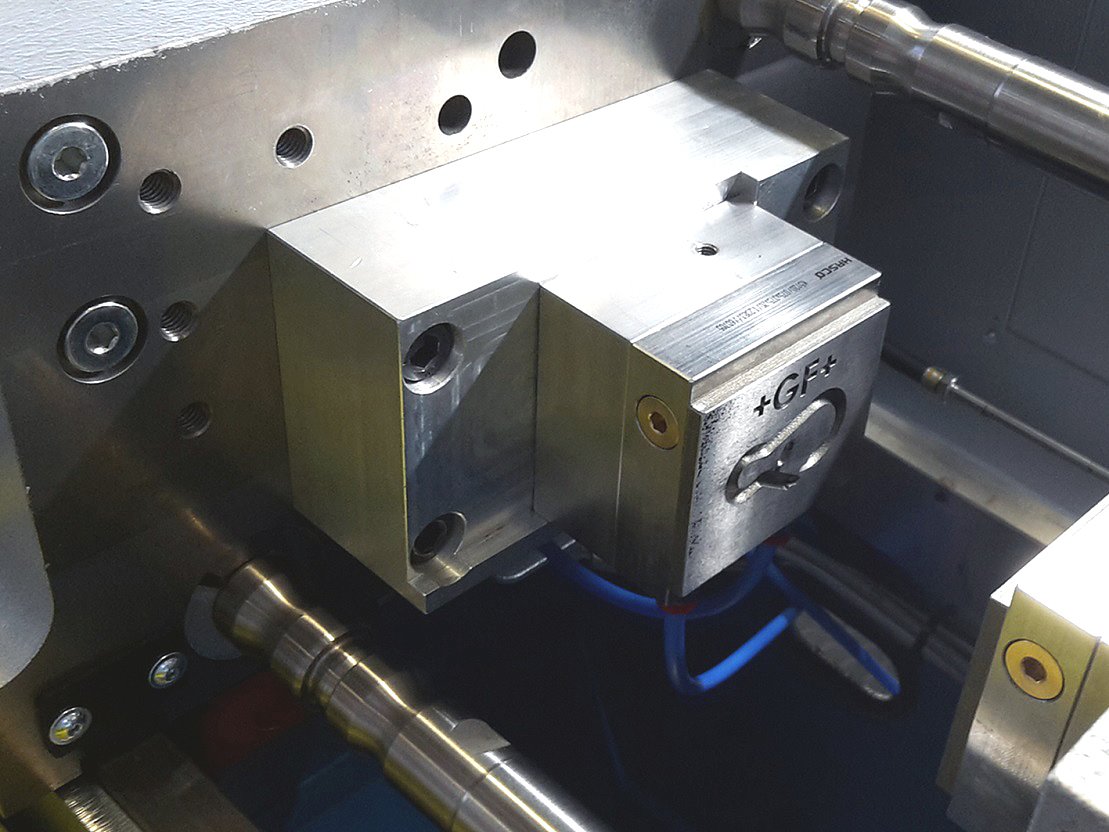

Over the past two years, 3D-plastic mould inserts have revolutionized mould manufacturing in the plastics processing industry. Low mould costs due to 3D-printed mould inserts as well as the rapid implementation of modifications are the decisive advantages for the users. A drop of bitterness, however, is their durability. Higher temperatures of the materials and high injection pressures have a negative impact on the lifetime of the mould inserts. The operating cycles of the 3D-printed moulds decrease. Especially for small series and medium quantities, many users would like to have more stable solutions. This is guaranteed by the use of 3D-printed metal mould inserts. Higher stability and the possibility of a sometimes required mould temperature control / cooling are given with these metal mould inserts and thus represent the next stage of additive manufacturing.

A good preparation is most important

However, the layered pressure of the moulds made from plastic or metal differs significantly in terms of preparation and planning. In the case of metal mould inserts, a large number of marginal conditions have to be considered in advance. For example, for complex 3D-dimensional parts, tempering channels with the corresponding connections must already be provided in the planning stage of the mould inserts. In the case of the metal-printed moulds the parting line still has to be finished processed, because the structure of the surface of the mould part arises from the printing process. For the achievement of a defined or desired surface this additional processing step is therefore required.

If the technological and financial expenses of 3D-printed mould inserts for small quantities are manageable and significantly more efficient than conventional steel moulds, this is not the case for metal mould inserts, depending on their structure and complexity. At the beginning of the planning phase of the moulds or the metal mould inserts, decision should be made to either use a metal mould insert or a conventional aluminum- or steel mould. The design engineer should therefore be familiar with the potential of 3D-technology to create to a good and cheap mould, based on the additional possibilities.