The Hot Melt processing with hot melt adhesives can technically be settled between injection moulding and casting technique.

The possible applications of injection moulded parts are almost unlimited. However, the following main areas can be named:

- Overmoulding of plugs

- Overmoulding of protective sleeves

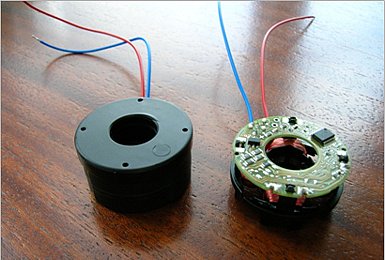

- Overmoulding of electronic components

Generally, a standard equipped BOY machine can sufficiently process hotmelt. Options are available to optimize individual applications.

The small amounts of hotmelt that need to be melted per cycle and its superior adjustability provide many advantages.

Compared to customary embedding machines, those are:

- Rapid colour change

- Little material loss

- Favourable for long flow distances

- Advantages regarding difficult wall thickness conditions

- Less material strain because of short well times

- Easy attainability of high injection speeds

- Good filling properties for voluminous parts

- Generally reduced investment cost

- Pratically all thermoplastic material (e.g. PVC, TPE and PA) can still be processed