Innovative into the future - BOY injectioneering

Dear customers and prospective customers,

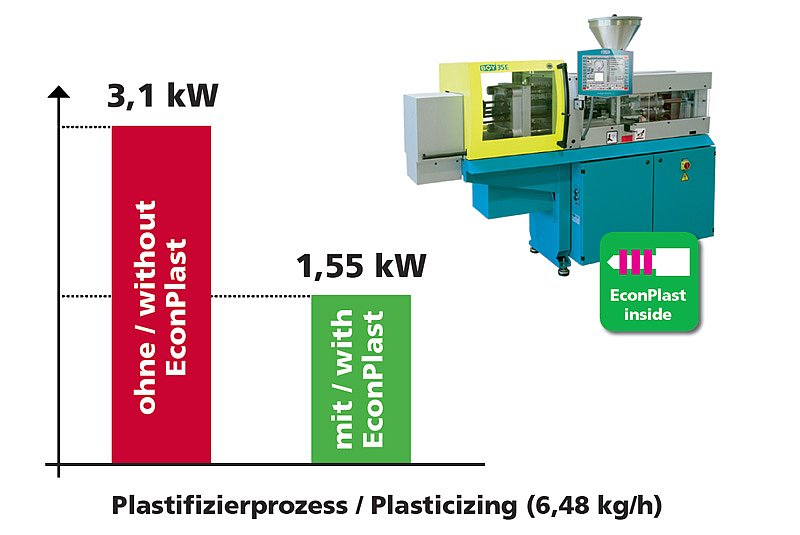

Save up to 50 % energy during plasticizing. Increase the effectiveness of your injection moulding machines by using our new EconPlast units. Reduce start and heating times, improve the temperature control and lower your reject rate.

In short: Reduce the part costs.

1. Introduction

For the processing of plastic during injection moulding, considerable amounts of energy are needed, since plastic first has to be melted (“plasticized“). As can be seen from illustration 1, the lion´s shares of the energy requirement of an injection moulding machine are the cylinder heating and the dosing. Therefore, it makes sense to begin at this point, the plasticizing process, to put an energetic optimization.

A part of the heat which is fed to the cylinder is discharged again to the surrounding via its surface. Also the feeding zone cooling (cooling ring which is flowed through with water, which prevents the excessive heating of the feeding zone and the involved premature melting of the material) withdraws the process energy.

The screw drive is effected hydraulically with the servo-motor pump drive. The servo motor moves a fixed displacement pump which carries oil from the tank into the line system. Then the oil is fed to the hydro motor (screw drive) via the control block and a valve. This converts the hydraulic energy into mechanic energy and ensures the rotation of the screw, which is located in the cylinder.

Energy losses which arise during the screw drive in servo motor, pump and hydro motor can be described through their efficiency factors. In addition due to friction, flow losses occur in the line system, the valve and the control block.

2. Energy balance in comparison

3. Main advantages of EconPlast

- Up to 40 % less energy requirement for the heating power

- Around 60 % less energy loss during dosing

- Faster and even more precise temperature control

- Thereby shorter start and heating times

- Lower reject rate due to material conservative and more low-friction processing of different materials

- Higher holding times of the EconPlast unit through high wear-resistant plasticizing units

- Improved feeding zone cooling with clearly lower energy losses

- Improvement of the material melting with optimized homogeneity

- Optionally available for all BOY injection moulding machines from a screw diameter of 24 mm

4. Benefit for the user

What is the benefit for the user of EconPlast units?

This question can be most impressively explained to an exemplary calculation:

Depending on the material throughput per hour and the number of operating hours per year results the amount of the saved energy costs. The higher the material throughput and the longer the operating time, the higher is the saving potential of energy costs.

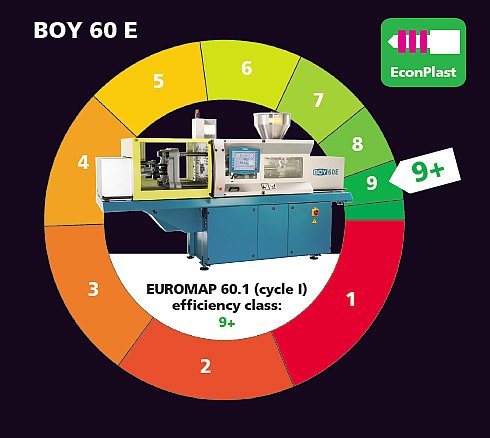

The material throughput of a BOY 60 E in three-shift operation is 14 kg / hour.

For the electricity supply price € 0,15 per kWh are estimated.

Energy costs of € 3528,- are saved per year.

The saved energy amount of 23,520 kWh in this example for plasticizing corresponds according to calculations of the German Federal Environmental Agency to a CO2 reduction of over 14 tons per year.

Calculate yourself:

5. Brilliant efficiency according to EUROMAP 60.1

6. Switch to EconPlast

More efficient plasticizing

All BOY injection moulding machines – from the ultra compact BOY XS with 100 kN clamping force over the insert moulding machines up to BOY 100 with 1,000 kN clamping force – work highly precise, reliable and extremely economical. Low machine hour rates are the basis for an even more cost-efficient part production.

Benefit also from this advance. We will be glad to advise you. Further information can be requested by telephone, email or fax.