Insert moulding technology / Insertion process

For almost 45 years, BOY has been constructing insert moulding machines with vertically arranged clamping units for the overmoulding of inserted parts.

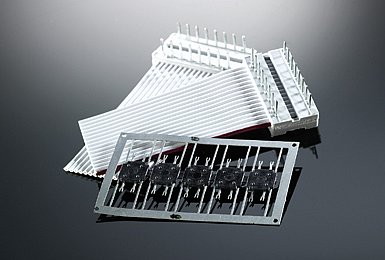

Long-standing experience is the basis for the precision and efficiency of these insert moulding machines with a clamping force range of 100 to 550 kN. The design advantage of this series is the fixed lower platen, which inhibits a shifting of the inserted part during mould closing.

With the ideally suited basic concept of a two-platen clamping unit, the continuously improved variable delivery pump system, and the latest-state-of-the-art Procan ALPHA control, the insert moulding machines are an excellent means of production.

For parting line applications, we also offer the BOY 22 VH with a horizontal injection unit. With this machine, cavities placed in the middle of the mould can be gated on one side in the split area, so that no gate marks will be visible on the surface of the moulded part.

BOY: Fully developed designs for horizontal and vertical injection moulding

BOY also has insert moulding capabilities due to the versatile design of their injection moulding machines. The BOY designers benefit from the practical experiences of moulders. They have always been an integral part of the continuous improvement and optimization of BOY injection moulding machines. Due to the easy accessibility to all parts of the Boy machine, short changeover times are normal and due to the innovative Procan ALPHA control, a smooth machine operation is standard.

The following applications and special solutions are possible on BOY injection moulding machines: Thermoplastic, elastomer, silicone, PIM, hotmelt, insert moulding, micro injection moulding, and clean room techniques.