Energie und CO2 einsparen durch Investieren

Profitieren Sie nicht nur von den aktuellen Fördermaßnahmen zur Energie- und Ressourceneffizienz in der Wirtschaft

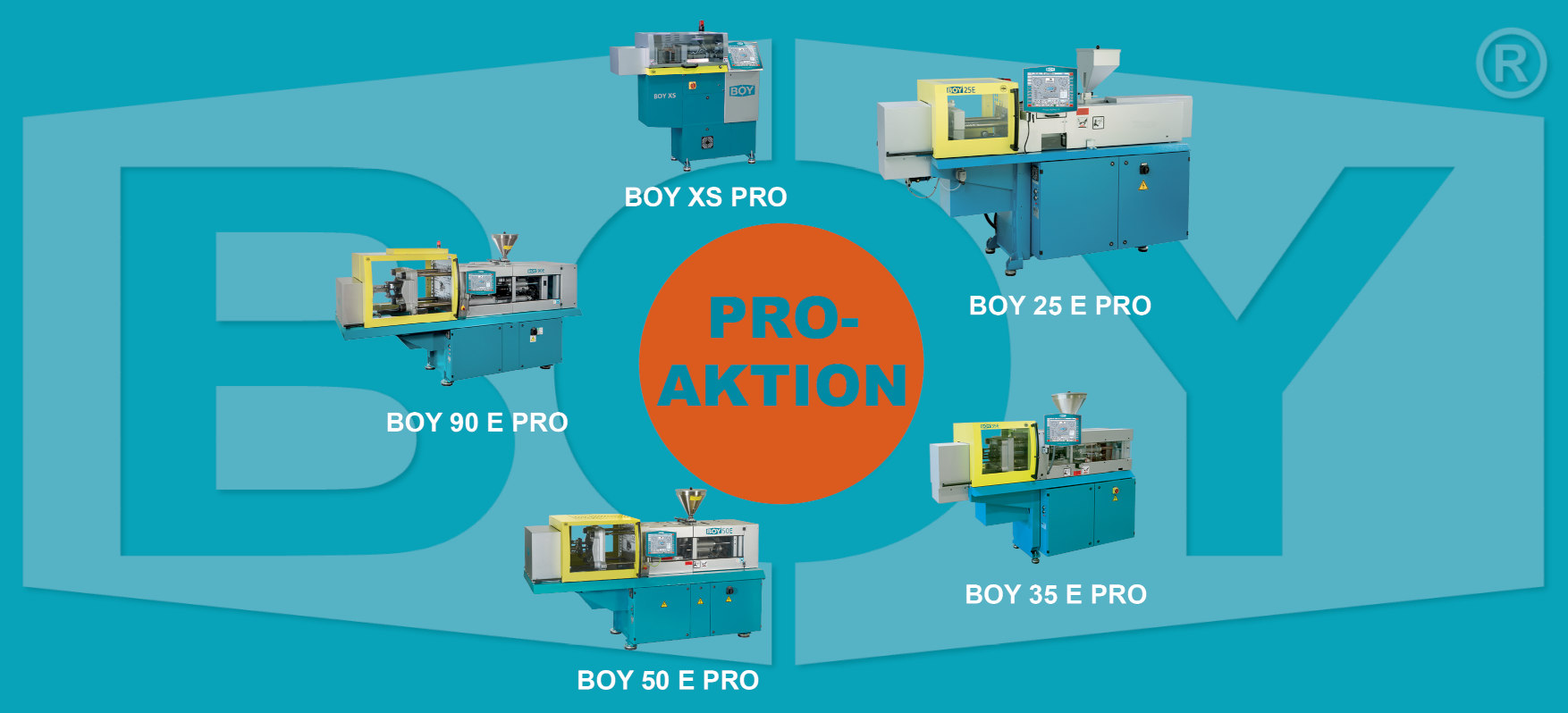

Injection moulding machines from BOY

Nearly 50,000 BOY injection moulding machines during the past 50 years

BOY's success story began in 1968 with the introduction of the BOY 15. The machine's compact design, ease of operation, it's economic efficiency and other important technical solutions revolutionized the fully automatic production of injection moulding machines.

But the BOY team never rested on it's laurels. On-going research programs led to further improvements. Today BOY offers a full range of injection moulding machines that are designed to meet all types of applications. Since the company was founded in 1968, BOY has supplied nearly 50,000 machines to all five continents. BOY has become the leading supplier for injection moulding machines with clamping forces up to 1.250 kN.

It does not matter if you intend to produce gear wheels with a diameter of 2 mm or frisbees with a diameter of 300 mm, BOY offers the optimum technical solution for you.