Thermoset processing

Thermal resistance and electrical insulation are the advantages of thermoset parts. We offer special plasticizing units for the production of such parts. With geometries developed for this purpose, all mouldable thermoset materials can be processed on BOY injection moulding machines.

Application: Granulated, chemically crosslinked thermoset moulding compounds.

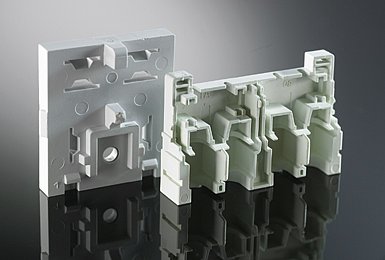

Application examples: Bobbins, parts for the electrical industry (e. g. fuse boxes), pot handles, belt tensioners, and other high-security applications.

Cylinder temperature is controlled by a heating-cooling fluid via external control unit.

- Screw without non-return valve.

- Coining and venting are available as options (BOY 50/60 and BOY 80/100/125).

- Mould temperature control via control loops in the machine (electrical heating elements are part of the mould).

- Air blast programs for mould cleaning is optional.

Innovative injection moulding techniques for all applications in plastic processing

BOY sold about 50.000 injection moulding machines all over the world during 50 years. Today, BOY is a well-known supplier of numerous special techniques in the plastics industry. During this time, BOY has become a well-known supplier of machines designed for many applications. Besides the processing of thermoplastics, BOY designed special machine configurations for different applications and special materials through continuous research and the support of customers and well-known specialists. These special designs and technical development capabilities has enabled BOY to meet every special application in the plastics industry.

The following applications and special solutions are possible on BOY injection moulding machines: Thermoplastic, elastomer, silicone, PIM, hotmelt, insert moulding, micro injection moulding, and clean room techniques.