Previous

Klares Zeichen in Richtung Zukunft gesetzt

Inbetriebnahme der Photovoltaikanlage Anfang Juli 2023

Energie und CO2 einsparen durch Investieren

Profitieren Sie nicht nur von den aktuellen Fördermaßnahmen zur Energie- und Ressourceneffizienz in der Wirtschaft

Energiespar - Seminar

Unser Beitrag zum Energiesparen: Bis Jahresende bieten wir das Energiesparseminar kostenfrei an

Erfassungsbogen Maschinentausch

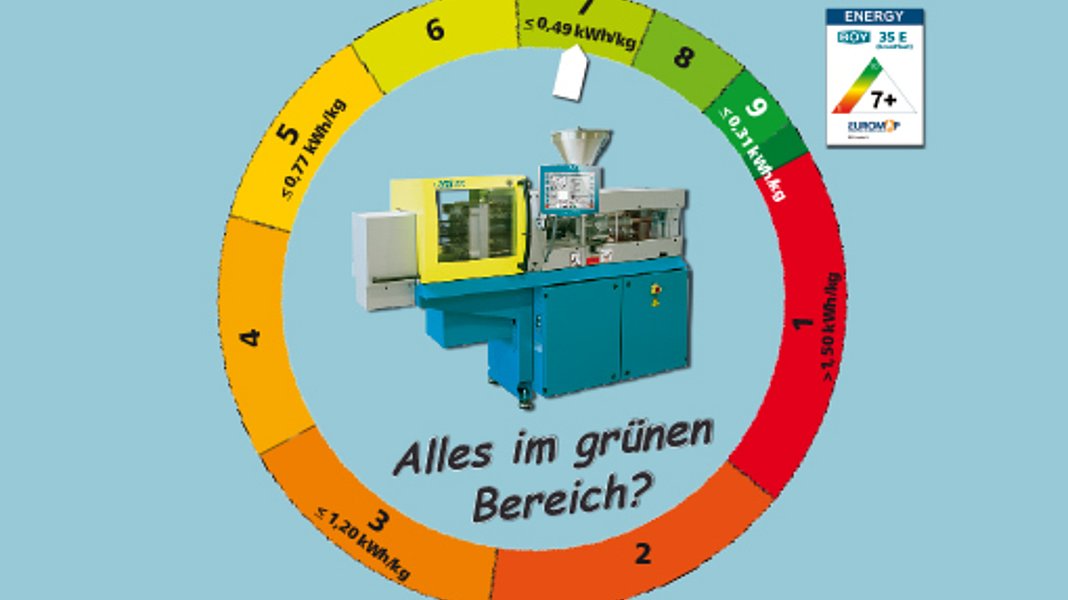

Austausch von weniger effizienten Spritzgießmaschinen

Premiere auf der K 2022: Die neue BOY XS E

Die neue BOY XS E tritt somit die Nachfolge der weltweit erfolgreichen BOY XS an, die seit 2009 in vielen Branchen für den industriellen Dauerbetrieb eingesetzt wird.

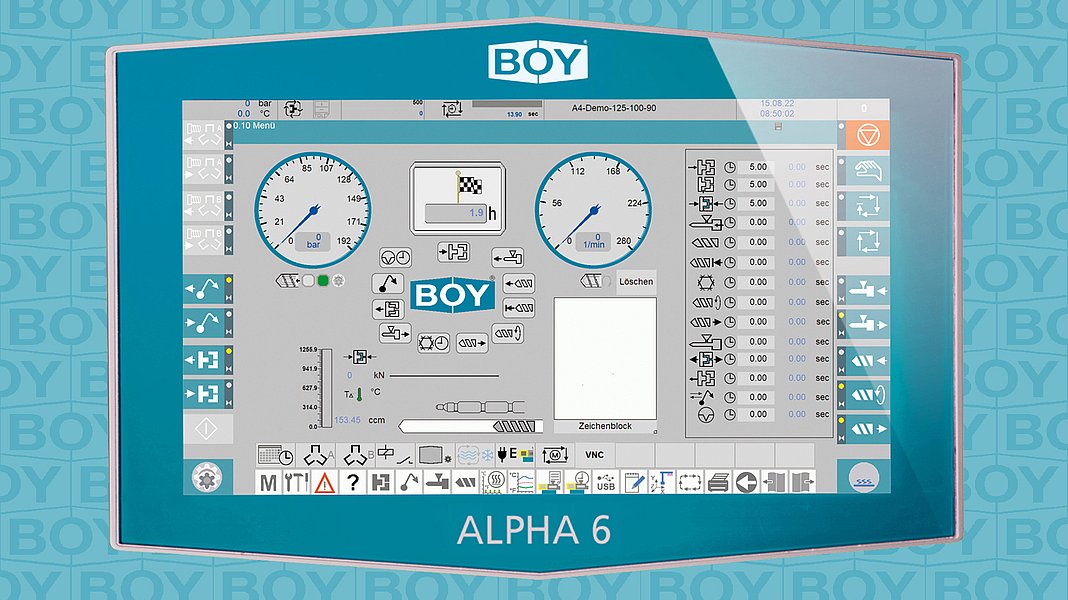

BOY-Maschinensteuerung im neuen Format

Die ALPHA 6 – der designierte Nachfolger der noch aktuellen Steuerung Procan ALPHA 4 – ist sofort am Bildschirmformat 16: 9 erkennbar. Das TFT-Farbdisplay der ALPHA 6 hat eine Full-HD Auflösung mit 1920 x 1080 Pixeln (px) und agiert mit der...

Online-Support per WLAN-Stick und Repeater-Server

Das Trendthema Digitalisierung greift BOY mit der Vorstellung seines WLAN-Sticks auf. Dadurch lassen sich BOY-Spritzgießautomaten mit der Steuerung Procan ALPHA ® 4 einfacher und ohne kabelgebundene Anbindung in ein beliebiges Netzwerk mit...

Moulding Assist von BOY

Mit diesem intelligenten Assistenten können aufgetretene Spritzgießfehler identifiziert werden. Der digitale Helfer liefert dem Anwender direkt an der Spritzgießmaschine Lösungsvorschläge zur Beseitigung der Spritzgießfehler.

E-Auswerfer

Neu ist ein elektromechanischer Auswerfer, der eine exakte Wegepositionierung des Auswerfers mit Synchronisierung von Auswerfer, Schließ- und Handlingbewegung ermöglicht.

![[Translate to English:] [Translate to English:]](https://www.dr-boy.de/fileadmin/_processed_/a/1/csm_Energiesparseminar_d719896f7c.png)