Maximal performance

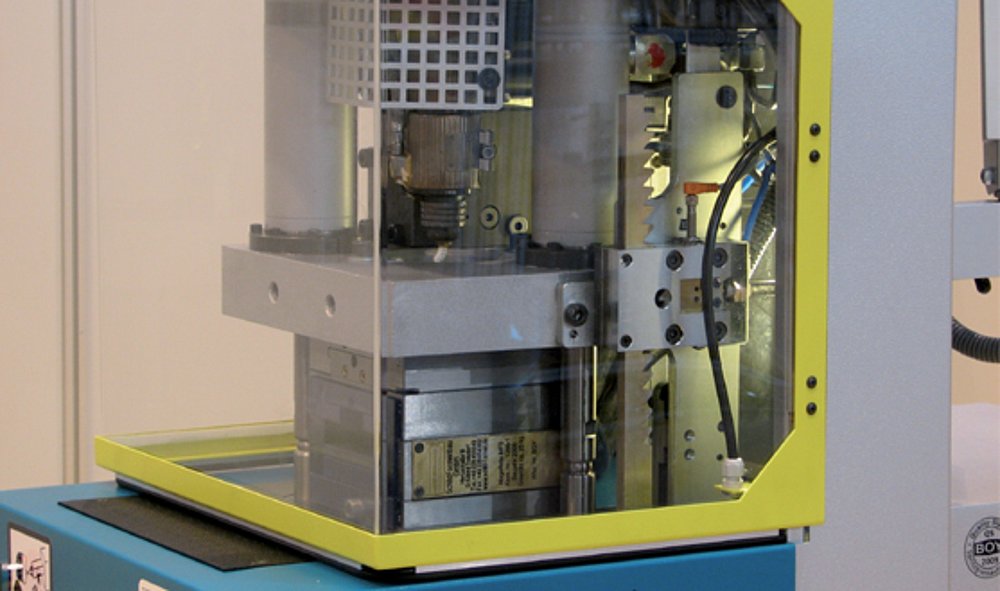

Insert moulding machine BOY XS V

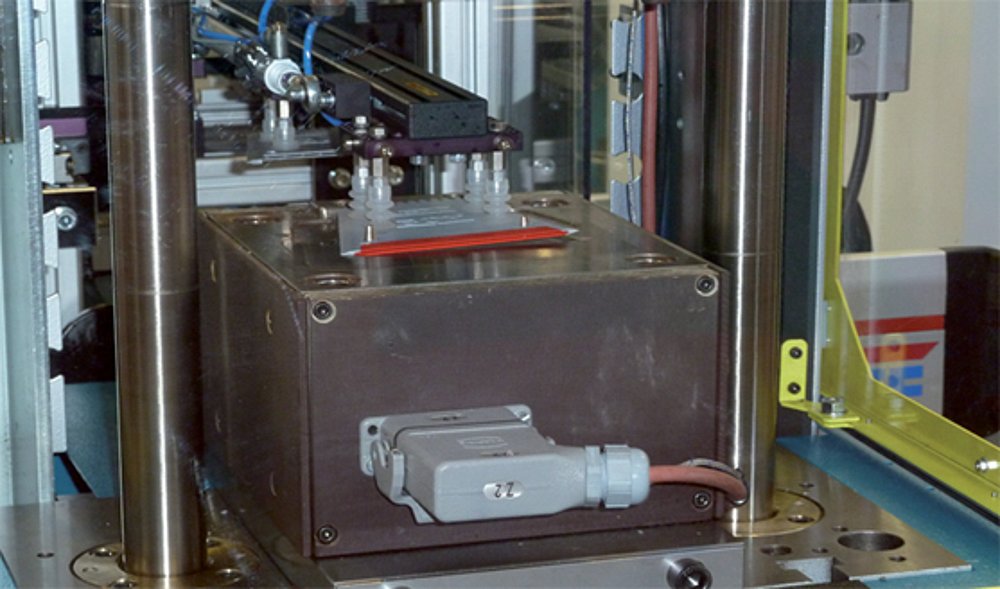

The BOY XS V features vertically arranged clamping and injection units. Being the smallest model, it supplements the reliable series of BOY insert moulding machines. This machine is suited to overmould metal parts, semi-finished parts or, for example, also cable endings.

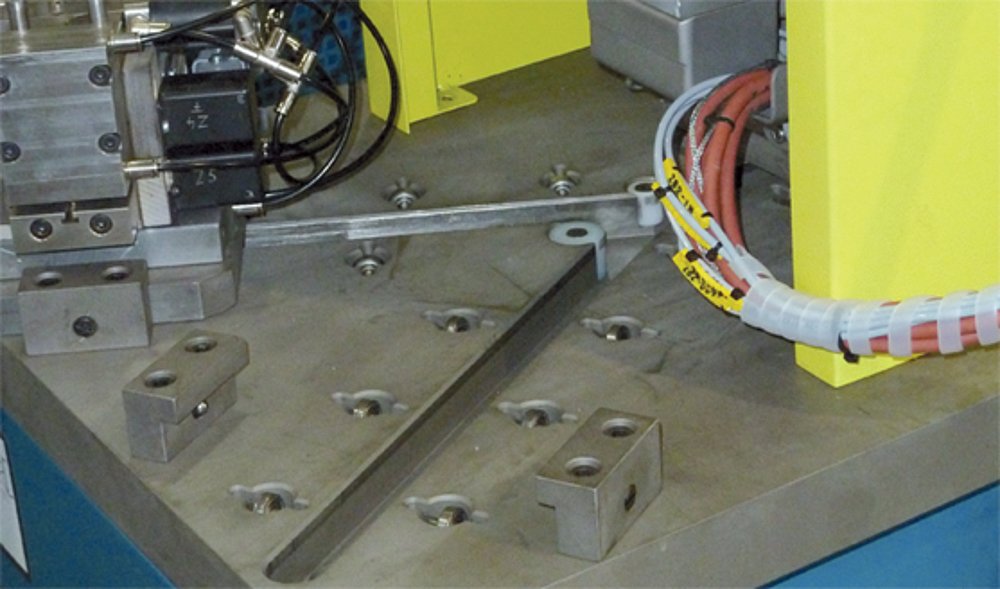

The fixed lower platen prevents the inserted parts from shifting during mould closing. The two-platen clamping system, in connection with the diagonally arranged tie bars, ensures best possible access from all sides, also for the insertion and removal of parts, as well as other automation equipment.

Furthermore, the machine is ideally suited for integration into a production line.

Facts

- Insert moulding machine

- clamping and injection units vertically arranged

- ultra-compact

- only 0,64 m² footpring

- 100 kN clamping force

- perfect for Micro-injection

- maximum efficiency

- lower energy demand

- ideal for long term operation

- flexible use of moulds

- comfortable operation

- Procan ALPHA 4 control

- easy automation

- worldwide service

Specifications

| Euromap Size: 100-3 / 100-14 |

| Screw Diameter: 8, 12, 14, 16 mm |

| Max. Stroke Volume: 8.0 cm³ (theoretical) |

| Max. Injection Flow: 36.8 g/s (theoretical) |

| Max. Spec. Injection Pressure: 3128 bar |

| Max. Daylight Between Platen: 250 mm |

| Max. Opening Stroke: 150 mm |

| Distance Between Tie Bars: 160 mm |

Downloads

- Raumbedarfsplan BOY XS V246 KB

- Einbaumaße BOY XS V179 KB