BOYs top-model

Injection moulding machine BOY 125 E

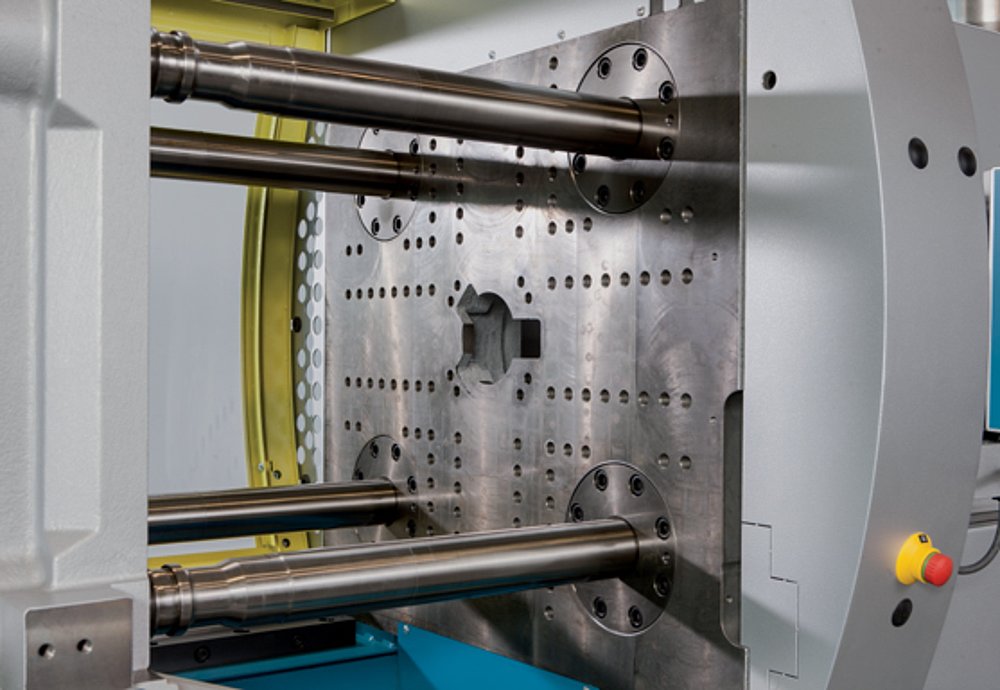

Significantly stronger, larger and more powerful, were the requirements for the development of BOY 125 E. In addition to the larger tie bar distance of 470 mm and a maximum platen distance of 825 mm, the new BOY top model offers a clamping force increase of 25%. 1.250 kN clamping force characterizes now the new machine upper limit at BOY.

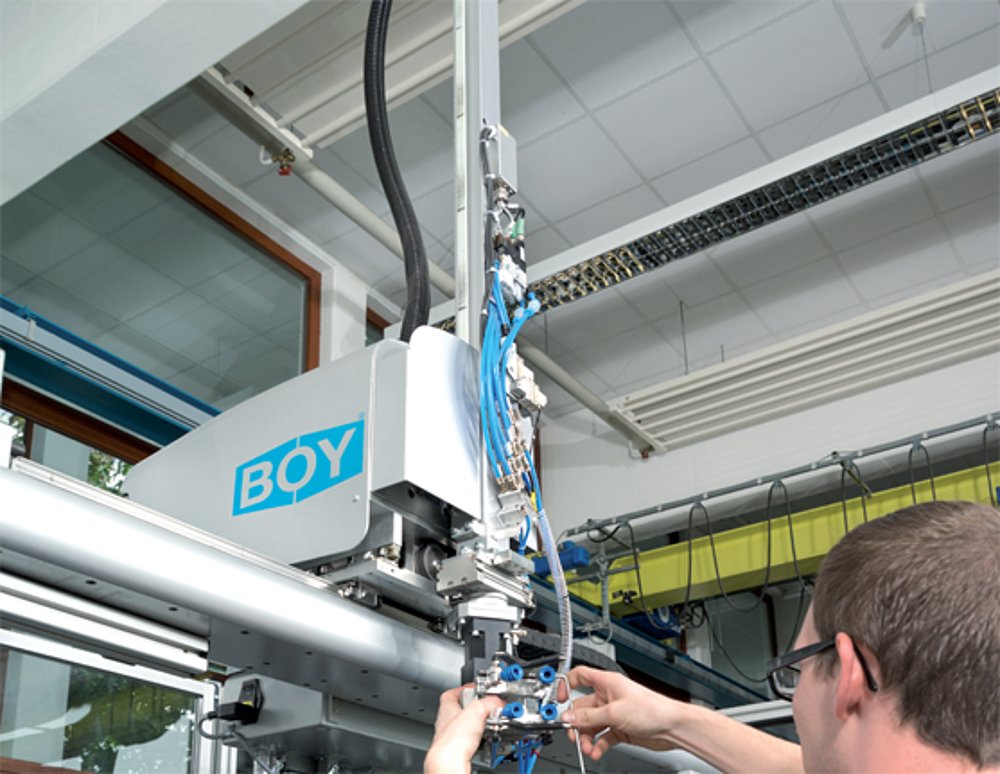

Given the easy handling of the machine, the users of the BOY 125 E enjoy maximum flexibility. All components - from the injection unit to the four-tie bar clamping system - are easily accessible. The divided safety gate of the

clamping unit is easy to open and offers optimum accessibility of the mould, which entails short set-up times and a rapid start of production.

Despite the many intelligent, balanced components and a multitude of optional equipment, the injection moulding machine from BOY makes do with little floor space (just under 5.22 square metres).

Facts

- Injection moulding machine

- top-model from Dr. Boy

- 1250 kN clamping force

- Servo-Drive

- moveable injection unit

- Two-Platen-clamping unit

- maximum efficiency

- maximum quality

- lower energy demand

- maximum precision

- flexible use of moulds

- comfortable operation

- Procan ALPHA 6 control

- easy automation

- worldwide service

Specifications

| Euromap Size: 1250-215 / 1250-420 |

| Screw Diameter: 28, 32, 36, 38, 42, 48, 52 mm |

| Max. Stroke Volume: 339.8 cm³ (theoretical) |

| Max. Injection Flow: 407.3 g/s (theoretical) |

| Max. Spec. Injection Pressure: 2798 bar |

| Max. Daylight Between Platen: 825 mm |

| Max. Opening Stroke: 525 mm |

| Distance Between Tie Bars: 470 x 430 |