Maximal performance

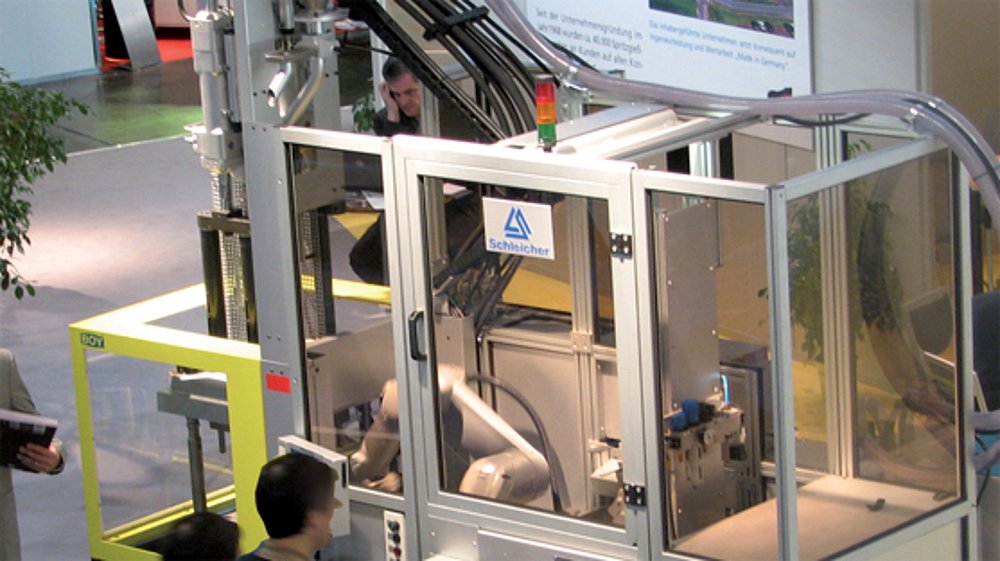

Insert moulding machine BOY 60 E VV

The largest BOY insert moulding machine now has a clamping force of 600 KN (performance increase of 50 KN more).

Compact dimensions and ample space on the machine frame for peripheral and optional equipment ensure optimum integration possibilities for automation systems.

Generous distances between tie bars furthermore offer enough space for mounting large and multicavity moulds.

The BOY 60 E VV features of a large shot volume, thus enabling large-volume over-moulding without problems. In total four screw diameters are available.

Facts

- Insert moulding machine

- ergonomic construction

- compact design

- small footprint

- 600 kN clamping force

- hydraulic drive

- Two-Platen-clamping unit

- maximum efficiency

- maximum quality

- lower energy demand

- ideal for long term operation

- flexible use of moulds

- comfortable operation

- Procan ALPHA 6 control

- easy automation

- worldwide service

Specifications

| Euromap Size: 600-56 / 600-69 / 600-82 / 600-215 |

| Screw Diameter: 18, 22, 24, 28, 32, 38, 42 mm |

| Max. Stroke Volume: 173.2 cm³ (theoretical) |

| Max. Injection Flow: 189 g/s (theoretical) |

| Max. Spec. Injection Pressure: 2798 bar |

| Max. Daylight Between Platen: 550 mm |

| Max. Opening Stroke: 300 mm |

| Distance Between Tie Bars: 360 x 335 mm |