well-proven construction

Injection moulding machine BOY XXS

The BOY XXS is a development from BOY - an injection moulding machine designed with well-proven technology and all the merits of our larger machines

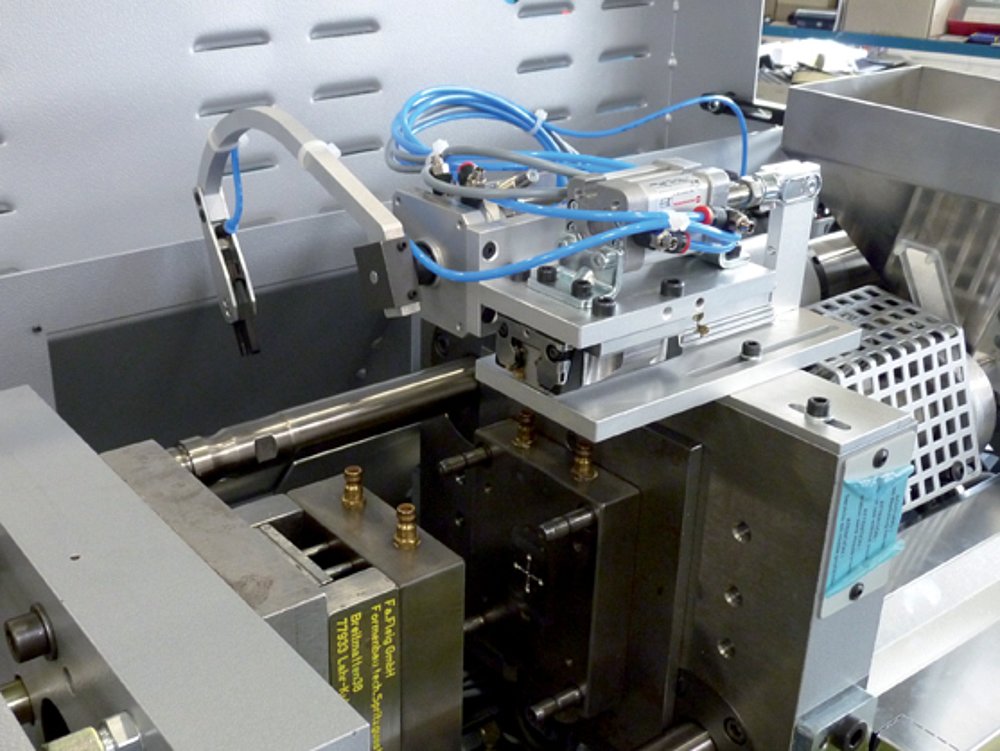

The difference: the BOY XXS is even more compact and thus offers new possibilities for micro and sprueless single-cavity injection-moulding in modern tabletop construction.

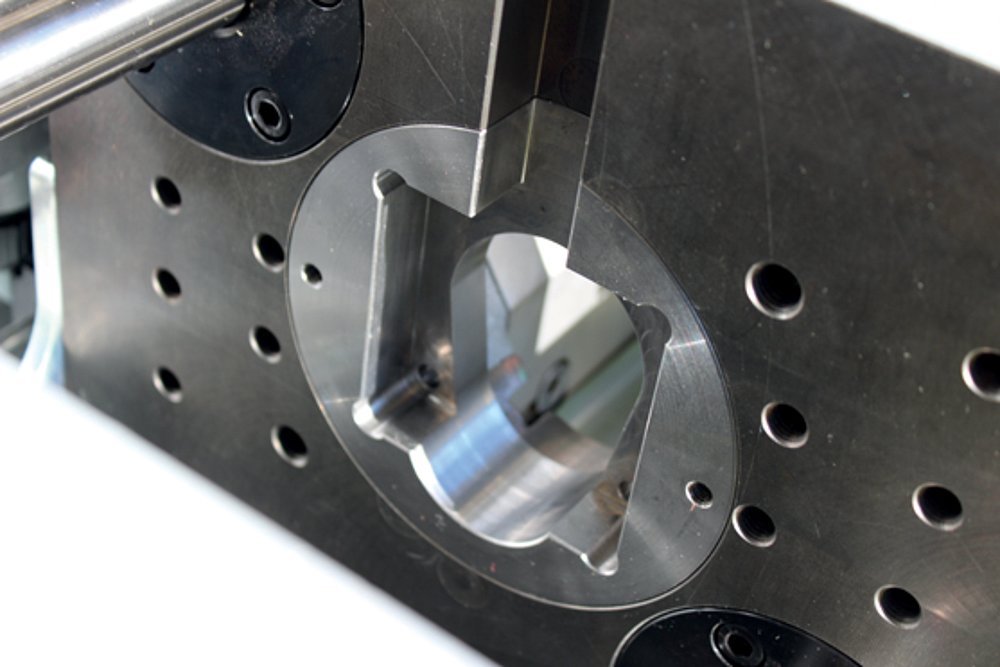

The mould fixing platens are specially designed to fit standard bolsters plate systems of most of the well known bolster manufacturers for micro moulds.

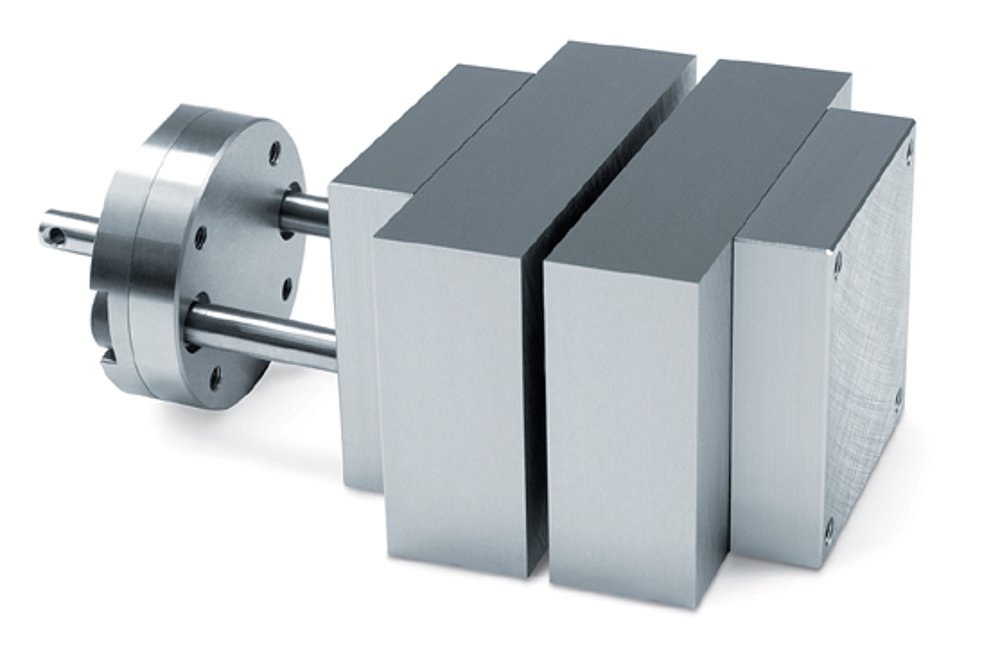

The BOY XXS is not equipped as common with this size injection moulding machines with a plunger type injection but with a reciprocating plasticizing screw with diameters from 8 to 18 mm working after the "first in first out" principal and with specific injection pressures up to 3128 bar.

The intelligent design is ideally suited for the requirements of micro injection moulding.

A 8 mm plasticizing unit assures shortest residence times - a great advantage for considerate processing of temperature-sensitive materials.

Facts

- Injection moulding machine

- ultra-compact

- only 0,89 m² footprint

- 63 kN clamping force

- perfect for Micro-injection

- maximum efficiency

- lower energy demand

- ideal for long term operation

- flexible use of moulds

- comfortable operation

- Procan ALPHA 4 control

- easy automation

- worldwide service

Specifications

| Euromap Size: 63-3 / 63-14 / 63-23 |

| Screw Diameter: 8, 12, 14, 16, 18 mm |

| Max. Stroke Volume: 15.3 cm³ (theoretical) |

| Max. Injection Flow: 46.3 g/s (theoretical) |

| Max. Spec. Injection Pressure: 3128 bar |

| Max. Daylight Between Platen: 180 mm |

| Max. Opening Stroke: 110 mm |

| Distance Between Tie Bars: 160 mm |

Downloads

- Raumbedarfsplan BOY XXS297 KB

- Einbaumaße BOY XXS270 KB