Maximal performance

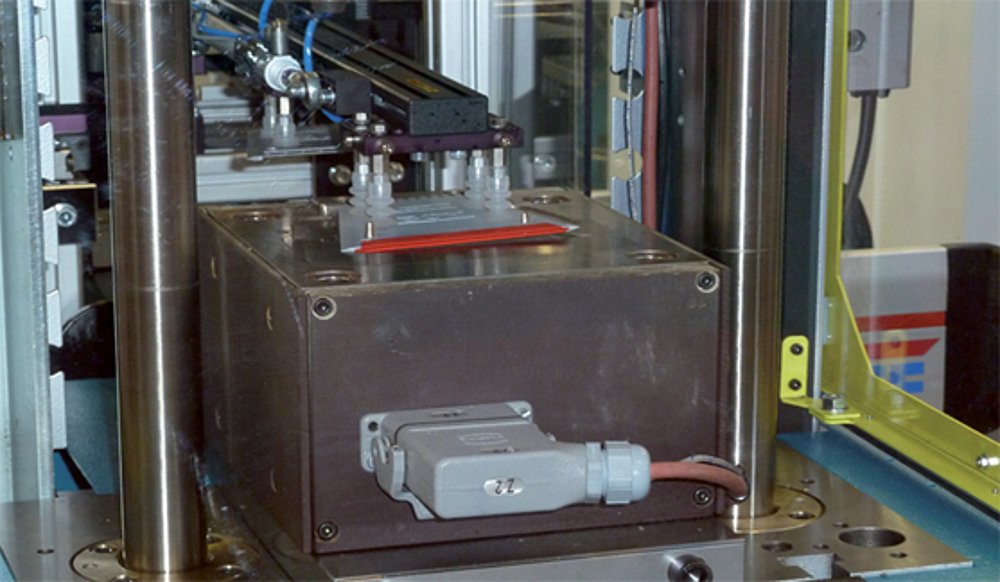

Insert moulding machine BOY 25 E VV

With a clamping force of 250 kN, the BOY 25 E VV insert moulding machine fills the gap between the BOY XS V (100kN) and the BOY 35 E VV (350kN). The BOY 55 E VV completes the BOY insert moulding machine series.

This reliable BOY machine series has proven itself for over 35 years in thousands of applications worldwide. The advantage of BOY insert moulding machines is in its basic design of a two platen clamping unit with a fixed lower platen.

The BOY 25 E VV, the successor to the very successful BOY 22 A VV, has clearly been improved in terms of efficiency, clamping force, quietness, and accessibility. In addition, the footprint has been reduced by nearly 11%.

Users appreciate in addition the good working ergonomics; suitable working heights result in a small distance to the mould space.

Up-to-date Hydraulics

The hydraulic pump on the BOY 25 E VV compared with the previous model provides an increase in delivery volume as well as faster and more dynamic travel speeds. Flow and friction resistance are reduced considerably by the hydraulic system of the clamping unit. As a result, the cycle time according to EUROMAP 6 is decreased to about one second.

Facts

- Insert moulding machine

- clamping and injection units vertically arranged

- compact design

- only 1,39 m² footprint

- 250 kN clamping force

- hydraulic drive

- Two-Platen-clamping unit

- maximum efficiency

- maximum quality

- lower energy demand

- ideal for long term operation

- flexible use of moulds

- comfortable operation

- Procan ALPHA 6 control

- easy automation

- worldwide service

Specifications

| Euromap Size: 250-11 / 250-16 / 250-39 / 250-56 / 250-69 / 250-82 |

| Screw Diameter: 12, 14, 18, 22, 24, 28, 32 mm |

| Max. Stroke Volume: 76.5 cm³ (theoretical) |

| Max. Injection Flow: 111.2 g/s (theoretical) |

| Max. Spec. Injection Pressure: 2739 bar |

| Max. Daylight Between Platen: 400 mm |

| Max. Opening Stroke: 200 mm |

| Distance Between Tie Bars: 254 mm |